Textiles in civil engineering - Benefit from rethinking.

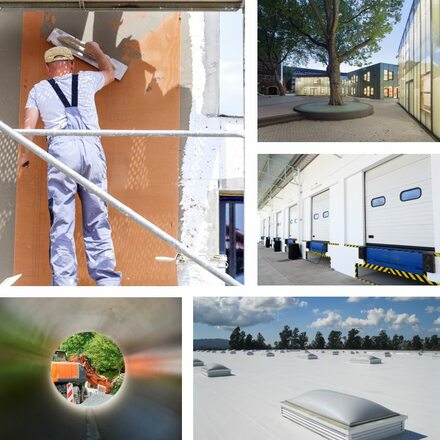

The civil engineering business undergoes a radical change, and is in search of innovative solutions with high efficiency and low resource consumption. You should also benefit from this rethinking! Use the machines of KARL MAYER Technical Textiles in order to produce textile concrete reinforcements, roof materials and plaster grids, thus, making building and renovating easier, more eco-friendly and faster. Or you can manufacture geogrids and composite structures for infrastructure projects, that offer various functions in a well thought out material composition.

KARL MAYER offers a width range machine portfolio with customized machine solutions for your projects. With our flexible machines we can guarantee a efficient production of textiles for the entire application area of civil engineering.

Application Overview

-

Plaster grids

By embedding the reinforcing fabric, an effective increase of the crack resistance in the plaster is achieved and undesired crack formation, e.g. due to vibrations, is avoided.

Article 11088 --> Explore more

Advantages:

|

Prevention of cracking and spreading of cracks Prevention of cracking and spreading of cracks

|

|

Optimum force distribution Optimum force distribution

|

|

Increased life time Increased life time

|

-

Roofing

The textile reinforcements of single ply roofings adds strength and durability to complete system.

Article 11087 --> Explore more

Advantages:

|

Cost-effective roofing system Cost-effective roofing system

|

|

Flexible and stable material Flexible and stable material

|

|

UV resistant + Energy saving because of reflecting the s UV resistant + Energy saving because of reflecting the s

|

-

Panel Walls

The use of panel walls made of fiber-reinforced plastic makes it possible to reduce the amount of material used, save unnecessary weight and integrate useful functions into the applications.

Article 50064a --> Explore more

Advantages:

|

Impact resistant material Impact resistant material

|

|

High heat resistance High heat resistance

|

|

Lightweight construction Lightweight construction

|

-

Building reconstruction

The use of textile reinforced concrete offers significant advantages in the field of repair and reconstruction of steel concrete structures.

Article 11062 --> Explore more

Advantages:

|

Lightweight & easy handling Lightweight & easy handling

|

|

Emission reduction & saving resource Emission reduction & saving resource

|

|

Increased service life due to the absence of corrosion Increased service life due to the absence of corrosion

|

-

Safety gates reinforcement

The textile reinforcement provide an ultra thin and effecient protection against the most common power tools.

Article 11139 --> Explore more

Advantages:

|

Proctection against the most common power tools Proctection against the most common power tools

|

|

Quick and easy installation Quick and easy installation

|

|

Ultra thin and lightweight construction Ultra thin and lightweight construction

|

-

Pipe repair

Trenchless repair of pipes requires minimal equipment and has little impact on the environment, which results in a small carbon footprint.

Article 50064a --> Explore more

Advantages:

|

Cost savings by repairing the pipes instead of replacing them Cost savings by repairing the pipes instead of replacing them

|

|

Environmentally friendly because no excavation of soil masses necessary Environmentally friendly because no excavation of soil masses necessary

|

|

Immediate recommissioning of the pipes Immediate recommissioning of the pipes

|

-

Base reinforcement

Geogrids and geocomposites enable an immediate increase in the bearing capacity of the soil and also achieve a uniformity of subsidence in the subsoil.

Article 10882 --> Explore more

Advantages:

|

Improving the bearing capacity of sub grades Improving the bearing capacity of sub grades

|

|

Separation of sub grade layers Separation of sub grade layers

|

|

Filtration of the sub grade layers Filtration of the sub grade layers

|

-

Slope stabilization

The use of geogrids and geocomposites enables the construction of steeper, safer embankments to optimize land use and reduce the disruption of a structure.

Article 10882 --> Explore more

Advantages:

|

Excellent structural capacity Excellent structural capacity

|

|

Minimal impact on environmental area due to the optimize land use Minimal impact on environmental area due to the optimize land use

|

|

Significant cost savings compared to steel reinforced concrete structures Significant cost savings compared to steel reinforced concrete structures

|

-

Road/Track reinforcement

The use of geogrids improves the elastic modulus of a roadbed while distributing loads for greater roadway longevity and performance.

Article 11141a --> Explore more

Advantages:

|

Protection from reflective cracks Protection from reflective cracks

|

|

Redistributes stresses horizontally in the overall system Redistributes stresses horizontally in the overall system

|

|

Prevention of wheel track rutting Prevention of wheel track rutting

|

-

Wind energy

By using of textile-reinforced composites, it is possible to develop wind turbines with longer blades.

Article 50064a --> Explore more

Advantages:

|

High tensile strength due to the high-performance fibres High tensile strength due to the high-performance fibres

|

|

Renewable energy Renewable energy

|

|

Lightweight construction Lightweight construction

|

Increased life time

Increased life time

Cost-effective roofing system

Cost-effective roofing system

Lightweight construction

Lightweight construction

Environmentally friendly because no excavation of soil masses necessary

Environmentally friendly because no excavation of soil masses necessary