Yarn Feeding Devices

There are various systems available for tape yarns, monofilaments or filament yarns to the machine's knitting elements to produce nets. Each system invovles feeding the yarns to the knitting point via yarn combs and tensioners.

Depending on the lapping, the guide bars knit the yarns supplied from the various guide bars to produce different textile products.

Karl Mayer offers the following yarn feeding systems:

- an FTL unit

- a frame carrying sectional warp beams

- a combination of a sectional warp beam frame and an FTL unit

- Feed units with a creel

- Feed units with beam let-off frames

FIND YOUR SUITABLE YARN FEEDING SYSTEM

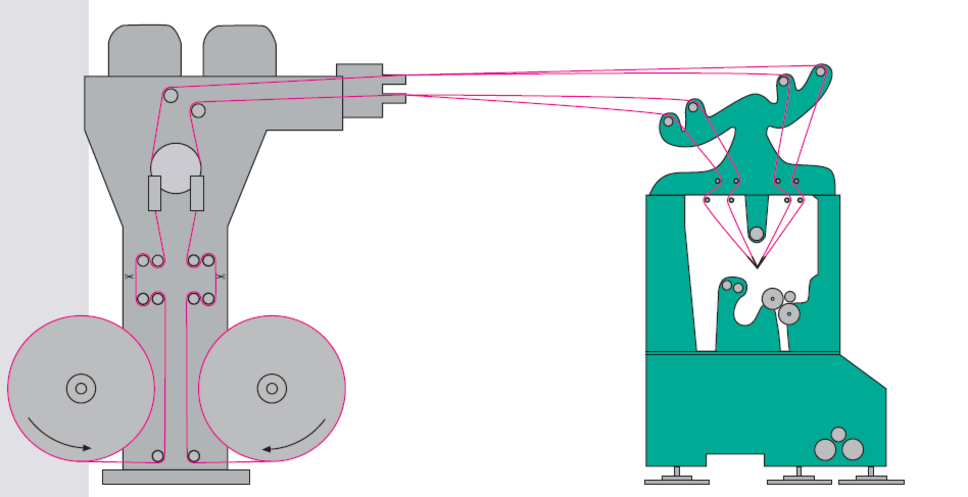

Operating with the FTL unit

The FTL unit is usually located behind the machine and is used for feeding the exact amount of tape yarns required to the machine. The FTL system is based on a modular design, and can be supplied as a single unit or as twin or triple versions. To determine how many units are needed will depend on the individual machine specification.

Advantages of the FTL

- Direct material flow

- High effectiveness due to short set-up times

- Low space requirement

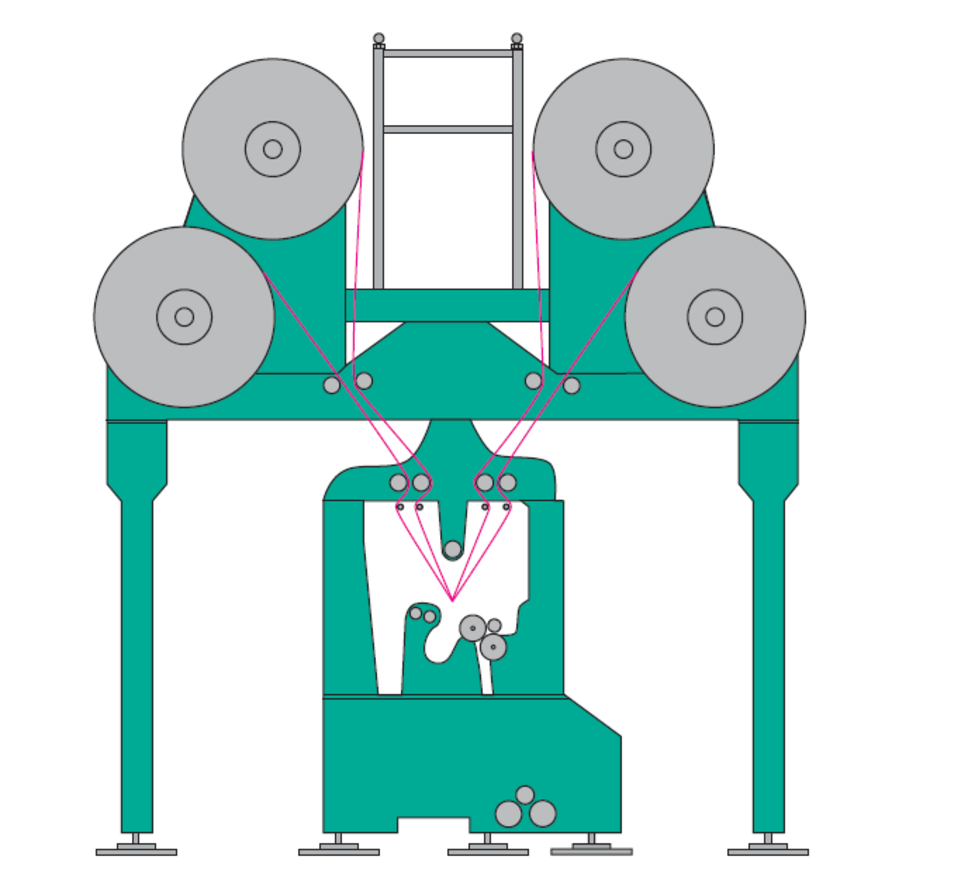

Operating with sectional warp beams

Wound packages (tape or monofilament yarns) are a basic prerequisite for processing sectional warp beams. To produce the sectional warp beams, the wound material must be processed onto sectional warp beams on a warping machine. The sectional warp beams are then mounted onto a frame, which is placed over the machine. The yarn is fed directly from the sectional warp beams via tensioning bars and combs to the knitting point. The number of beam mountings on the frame usually depends on the number of (ground) guide bars. Each beam station can carry several sectional warp beams, depending on the width of the machine, the number of yarns or monofilaments required, and the size of the sectional warp beams.

Advantages of Sectional warp beams

- Working with foil tapes and monofilament is possible

- Very low space requirement

- Good tension is achieved through the use of well-warped partial warp beams.

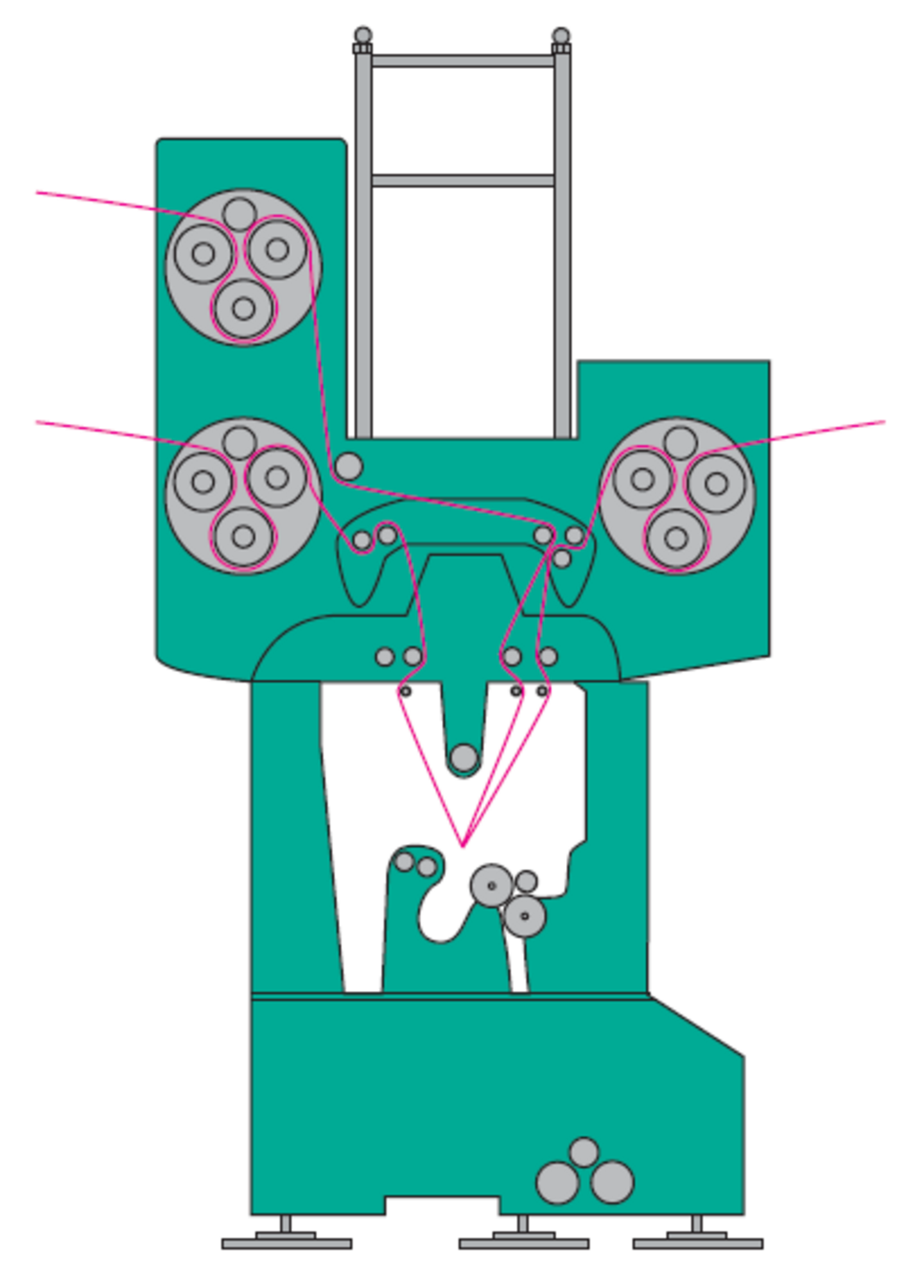

Operating with sectional warp beams and an FTL unit

Combining a frame with an FTL unit enables an article containing tape yarns as well as monofilament yarns to be produced. The tape yarns are fed from the FTL unit and the monofilaments are fed from the frame.

Operating with feed units

Feed units and a creel

Using a creel is always recommended if the yarn is wound of packages. The packages are mounted in the creel and the exact amount required is fed via feed units to the machine. There are a variety of creels available for different types of package mountings. The feed units are used to take-off the yarns from the creel and feed the tape yarns or monofilaments to the knitting point at the correct tension.

Advantages of feed units and a creel

- High efficiency, as the packages can be used directly

Feed units and beam let-off frames

If the aim is to achieve longer running times by using larger beams, the alternative is to position the beams on separte let-off frames rather than on a frame above the machine. The beams that are mounted on let-off frames are larger than standard sectional warp beams.

Advantages of feed units and beam let-off frames

-

Working with foil tapes and monofilament is possible

-

Good handling as trees are placed on floor frames

-

Even tension can be achieved