Jacquard

Meeting your wishes for unique and balanced patterns

A little bit of history...

Raschel machines, on which the warp threads are individually controlled by a Jacquard device, have been known since about 1884. The Jacquard apparatus as such is considerably older, going back to the year 1805, when it was invented by the French silk weaver Joseph Marie Jacquard (1752-1834).

The warp knitted Jacquard curtain machine was launched by Karl Mayer into the market by the mid-seventies and within 5 years saw the introduction of the first Multibar-Jacquard Raschel lace machine with an electronic control system, intended for the manufacture of high-quality lingerie and outerwear lace articles.

Today at Karl Mayer we use Jacquard technology accross a wide spectrum of our machines including Tricot, Rascheltronic®, Jacquardtronic®, Textronic®, Double needle bar and Jacquard curtain machines.

Jacquard technology offers a broad spectrum of end-uses

- Shoe fabric

- Curtains

- Lingerie

- Outerwear lace

- Functional shapewear

- Seamless athleisurewear

- Terry towels

So what is Jacquard and what does it do?

This depends on the kind of machine that has a Jacquard.

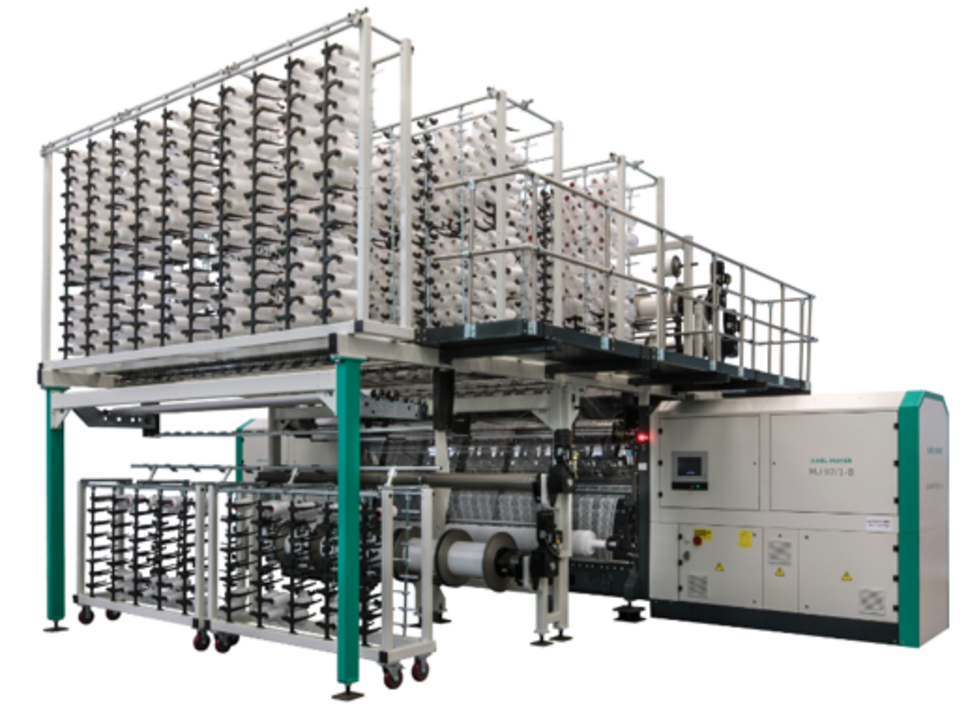

Jacquard Curtain machines

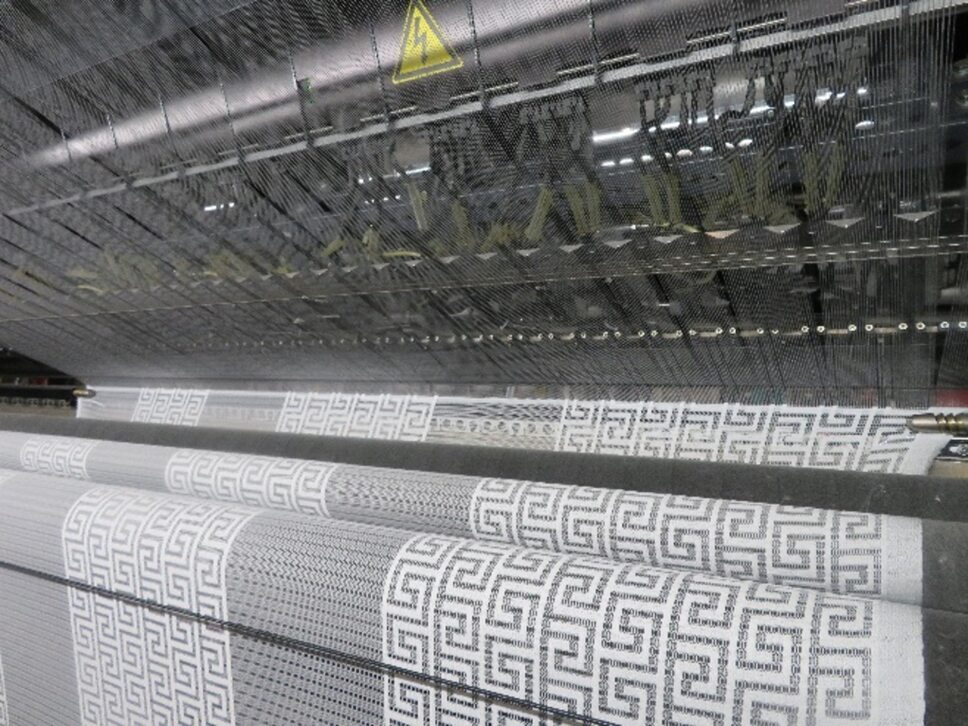

This machine is immitating bobbinet curtaining. The Jacquard is positioned at the front of the machine and acts as the patterning, so it usually has a heavy thread. For each needle and each course, the Jacquard device can be instructed to make a single tie, a double tie or a hole. On a modern machine this instruction is in the form of binary information which is sent to the piezo device which in turn controls each individual Jacquard guide, carring the heavy pattern thread.

This individual selection means that the pattern can be very complicated, although somewhat flat, offering only 4 different dimensions of depth or weight. Hence the name „flat Jacquard“ for this kind of curtain product.

Multibar Jacquard lace machines

For more dimension and complex patterning we need to turn to a multibar lace machine. These kind of machines combine pattern bars and a Jacquard. In this case the Jacquard is not used for the pattern but for the delicate net contructions which for the ground upon which the pattern bars create the design. In lingerie lace machines the Jacquard yarn is a finer count, typically dtex 44 flat Nylon.

The Jacquard function is fundamentally the same as the curtain machine, but nowadays the Jacquard is often placed at the back of the machine, in order that the pattern threads have more dimension and the Jacquard is more of a background element, the pattern threads being the star of the show.

Benefits of Jacquard

The Jacquard technology offers the following advantages:

-

Increased patterning possibilities

High quality fabrics

Ease of pattern development

High degree of automation

-

Versatility of end products

Increased complexity without reduced speed