HKS 4-M ON

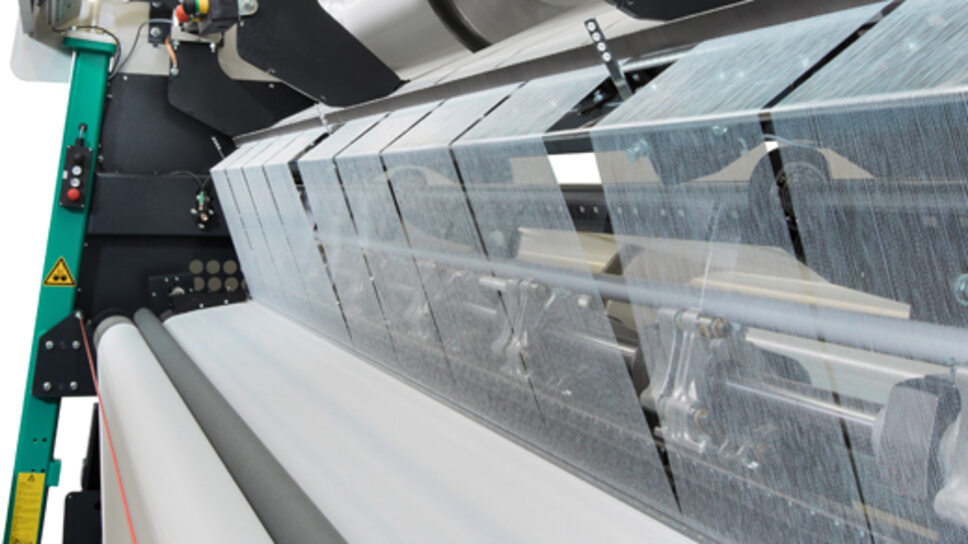

High-performance tricot machine with highest flexibility

For the production of rigid and elastic fabrics such as footwear, automotive interiors, outerwear, upholstery fabrics and velvets

New features

- KAMCOS 2®

- integrated lighting

- Spring Motion Assistant

- direct drive main motor

- improved warp beam support

- integrated camera option

- flexible patterning possibilities

- lowerable batching device for easier operation

- adjustable tension spring system

Machine Highlights

In addition to our renowned ON-technology, the HKS 4-M ON also offers the following advantages:

-

KAMCOS® 2

KAMCOS® 2Operator interface to configure, control and adjust the electronic functionality of the machine. Enlarged patterning possibilities by means of Multi Speed

-

Care Solutions

Care Solutions We offer customized packages, that combine spare parts & supplies, service & support and warp knitting knowledge.

>> explore more about care solutions -

The Spring Motion Assistant allows a quick, easy and safe change of guide bars without tools. At the push of a button the spring motion wire tension is released, and it can be removed with a simple tool such as a screwdriver. Spring Motion Assistant

Spring Motion Assistant

-

For improved maintenance costs and less energy consumption. Direct drive system

Direct drive system -

Improved warp beam support

Improved warp beam supportEasy and safe access to warp beam clamping positions through moveable ladders with multiple connecting positions on the front side of the machine and additional platform on the right side of the machine.

-

Uniform illumination of the working area. Machine operation status indicated through different colors. Integrated lighting

Integrated lighting

Patterning Possibilities

- Chain link editor on mobile device (cloud solution)

- k.innovation CORE (cloud solution)

- Import of existing pattern files or files from third party systems via Cloud

K.innovation

Web-based lapping editor for the HKS 4-M ON offered by our business unit KM.ON.

- Create your own lappings without the limitation to 36 stiches for more flexibility and innovation.

- Your patterns will be sent into the cloud and from there onto all of your machines worldwide

- Collaboration with a design tool enables creating from mobile devices as well as enhancement in communication between the people involved in the design process.

- Licensing model for flexible durations to fit the needs of the customer as well as minimizing financial risks.

WHAT THE PRODUCT OWNER SAYS

"Our latest generation of 4-bar tricot machines with electronic guide bar control was not only upgraded with our state-of the-art control system, but also integrated additional customer-friendly features – such as the spring motion assistant and our direct drive main motor, that increases the machines energy efficiency. Both technologies are already used in our 3-bar ON-series, and appreciated by our customers."

Kay Hilbert - Product Owner Global Tricot

Special Training Courses at our Academy

Only with the right knowledge and understanding of the machine and the new ON technology will you and your staff be able to outperform your competitors. Our academy offers you a special on site training focused on digitalization and new user friendly solutions of the machine.

Get more information about this special training here: SPECIAL TRAINING HKS 3-M ON & HKS 4-M ON

FIND YOUR PERFECT MACHINE

KARL MAYER is offering a wide range of working width for the HKS 4-M ON machines with various functions and possibilities. Please use the table below to find the suitable product for your future success.

| Machine specification | HKS 4-M ON | ||||

|---|---|---|---|---|---|

| Working width | 130“ + 6" | 180“ + 6“ | 210" + 8" | 260" + 8" | |

| Gauge | E 28, E 32 | E 28, E 32 | E 28, E 32 | E 28, E 36 | |

| Warp beam support | 4x32" (Standard) | ✓ | ✓ | ✓ | ✓ |

| 4x40" | ✓ | ✓ | ✓ | ✓ | |

| KAMCOS® 2 | Multi Speed | ✓ | ✓ | ✓ | ✓ |