4D-KNIT.SOLUTIONS

Double Needle Bar Technology is opening a new chapter

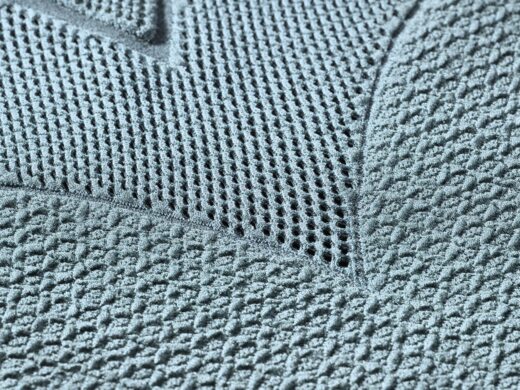

A clever bar arrangement and technical configuration combined with our established high quality KARL MAYER Piezo-Jacquard technology, enabling this innovative double needle bar machine to open up a new dimension: producing fabrics with diverse malleable patterning on both fabric sides. The 3D motives can be completely variable in shape, positioning and height. Small and flat reliefs or deep and bulky forms with cushioning are possible. Further, the design can contain freely placed holes, for even more possibilities. The openings can be used for directed air flow or lighting effects.

YOUR ADVANTAGES

3-Dimensional Design

The space between upper and lower can be filled with bulky yams to achieve unprecedented effects and 3D design together with excellent padding properties

Flexible design possibilites

4D-KNIT effect can be completly variable in shape positioning and height. Additional hole design for breathability and two-color effect can be created depending on the end user of the fabric.

Wide range of application

Depending on the amount of filling and design of the plastic motif , wide applications are available from cozy padded jacket fabrics to breahable textiles for functional shoes.

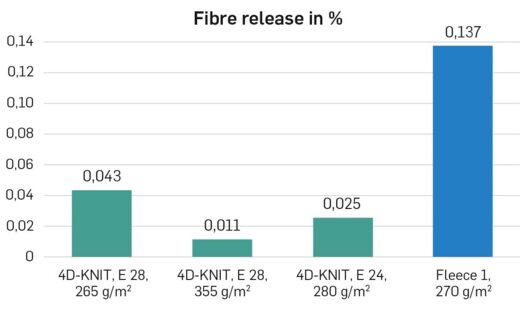

REDUCTION OF MICROPLASTIC

In addition to their good insulating properties and the completely new look, 4D-knit articles offer advantages in terms of environmental protection.The total fiber abrasion of the most favorable warp knitted fabric variant was only about 10% of the fiber abrasion of the fleece counterpart. In addition, for the 4D-knit fabrics, up to 84% fewer fiber counts were determined, the fleece sample had the highest number of fibers.

-

4D-knit softshell performance jacket

-

Environmental advantages compared to brushed fleece fabrics

-

Fig.: The microfibre consortium test method done at Hohenstein Laboratories in Boenningheim report no. 21.8.4.0431: Quantification of fibre release from fabrics during laundering by the filtration method

-

RDPJ 6/2 EL FB

The Double Needle Bar Machine for Jacquard Spacer market

Our RDPJ 6/2 EL FB is part of the successful RDPJ machine group. By using our Piezo-Jacquard technology, we can shape the fabric according to our customer’s needs.

- 4D-KNIT fabrics offer a new level of design potential

- High range of fabrics and applications

- Much higher productivity than other knitting technologies, with similar fabric appearance

>> Download Factsheet RDPJ 6/2 EL FB

>> Download 4D-KNIT Thermal resistance

MACHINE DETAILS

-

Speed500cpm

-

Working width

138" -

Gauge

E 24, E28 -

Trick plate distance 1,5-8mm -

Warp beam diameter6 x 32"

-

Control

KAMCOS® 2