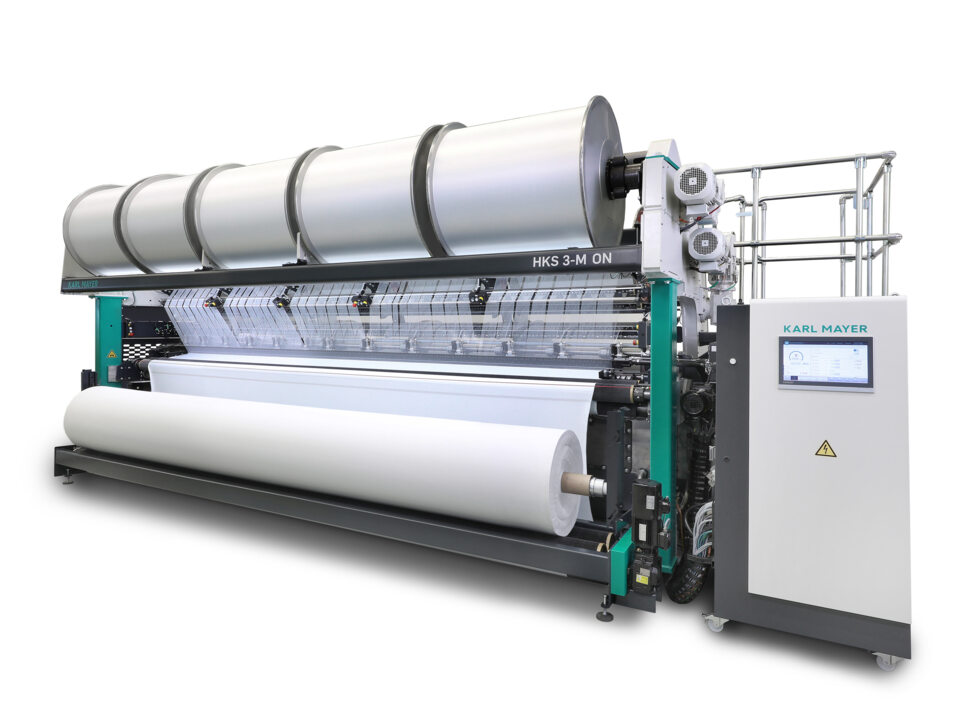

HKS 3-M ON

Bringing progress to our customers

High machine performance combined with newest technologies to improve useability and competitiveness of our customers

Features & Technologies

- Energy Data Ready

- Reproducible sinker positioning

- Integrated camera system with transmitted light set-up

- Lights for fabric check after take-up

- Improved warp beam frame structure

- Flexible patterning possibilities

Machine Highlights

In addition to our renowned ON-technology, the HKS 3-M ON also offers the following advantages:

-

State-of-the-Art Technology

State-of-the-Art TechnologyThe ON-drive pattern system with unlimited repeats, energy efficient direct drive solution, and user-friendly spring motion assistant – all these innovative features increase the efficiency of your production

-

Optimized Costs & Improved Sustainability

Optimized Costs & Improved SustainabilityMinimized maintenance costs and reduced energy consumption through direct drive system. Less costs for patterns compared to pattern discs

-

Quick, easy and safe change of guide bars without tools. At the push of a button the spring motion wire tension is released, and it can be removed with a simple tool such as a screwdriver Spring Motion Assistant

Spring Motion Assistant -

Prepare your business for the challenges in the modern business environment – immediate pattern change and higher productivity for a fast reaction to market demands. Maximize the effectivity of your factory space Efficient Production

Efficient Production -

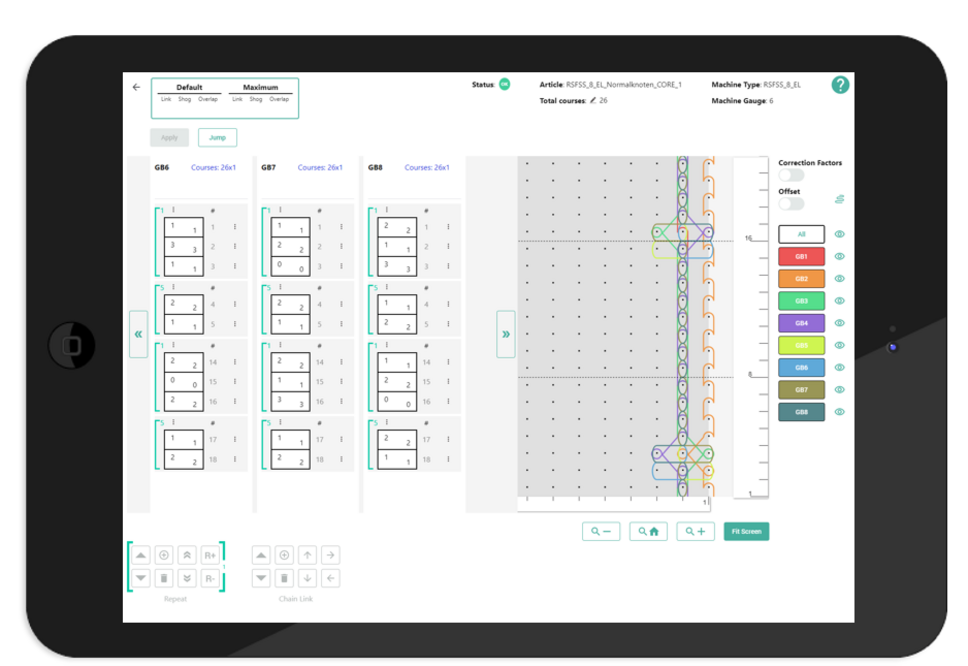

Digital KARL MAYER World

Digital KARL MAYER WorldEnjoy our digital offers to connect your machines for greater flexibility and competitivity

-

Improved Machine Design

Optimised machine design for user-friendly handling. Working platform infront of the machine for easy handling of larger fabric rolls. Easy and safe access to warp beam clamping positions through moveable ladders -

Master the challenges of the market with our HKS 3-M ON

PROFITABILITY & OPTIMIZED COSTS

- Reducing the TCO

- Energy efficiency

- Optimize maintenance costs

- Maximized factory utilization

SUSTAINABILITY & STAFFING

- Reducing our carbon footprint with cloud-based solutions

- Expanding our machines capabilities towards biodegradable and other sustainable yarns

- Simplifying and automating processes to reduce expertise on the shop floor

FLEXIBILITY & OPPORTUNITY

- Flexible patterning models for all customer’s needs

- Pushing the boundaries of machine production with new technologies

- Faster and easier availability of patterns and articles

Purchase Articles Online

You can now download pattern data files via our webshop into your k. innovation software.

FIND YOUR PERFECT MACHINE

KARL MAYER is offering a wide range of working width for the HKS 3-M ON machines with various functions and possibilities. Please use the table below to find the suitable product for your future success.

| Machine specification | HKS 3-M ON | ||||

|---|---|---|---|---|---|

| Working width | 130“ + 4" | 180“ + 6“ | 210" + 8" | 280" + (10"/20") | |

| Gauge | E 28, E 32 | E 28, E 32 | E 28, E 32 | E 28, E 32 | |

| Warp beam support | 3x32" (Standard) | ✓ | ✓ | ✓ | ✓ |

| 3x40" (Optional) | ✓ | ✓ | ✓ | ✓ | |

| 1x40", 2x32" (Upon request) | ✓ | ✓ | ✓ | ✓ | |

| KAMCOS® 2 | Multispeed (Optional) | ✓ | ✓ | ✓ | X |

Patterning Possibilities

Enjoy the flexibility in creating patterns with our latest pattern software k.innovation CORE lite! To find out more, please click here.