PROWARP®

PRODUCE WITH THE HIGHEST FLEXIBILITY, PRECISION, EFFICIENCY AND STRENGTHEN YOUR POSITION IN THE WEAVING MARKET

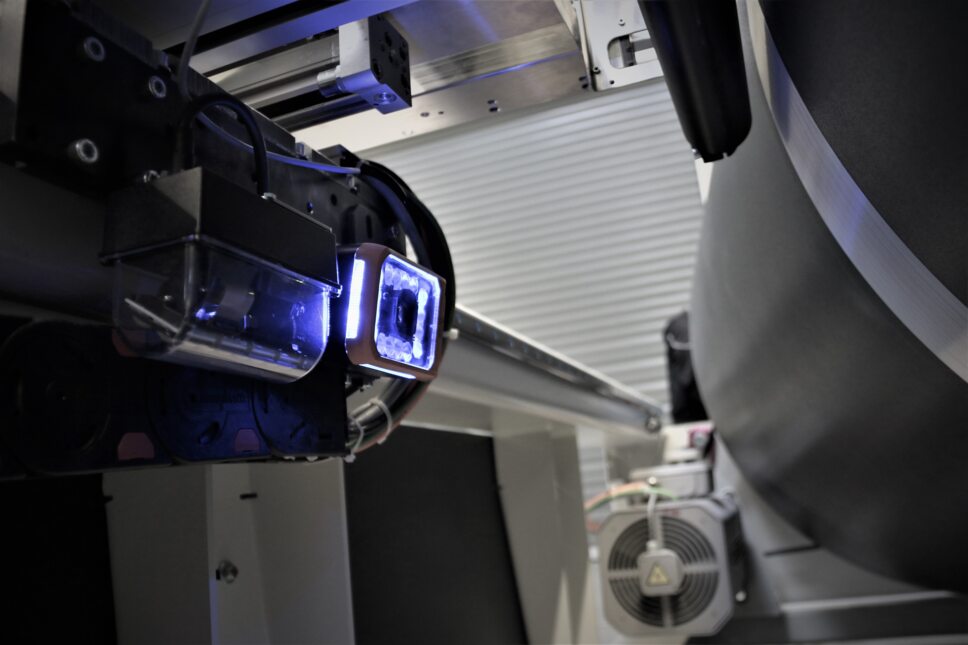

As an evolution of previous machine generations, PROWARP® can be called an „Allrounder". The machine has all variants of sensor technology, which can be adapted to all types of materials. It allows all options, no matter how demanding they are. The quality management is guided by the machine and is customizable for you. Through new systems such as the integration of the optical camera, the machine can optimize itself, which is unique in the weaving market.

Your Benefits

-

Innovative layer build-up system offers up to 30% more performance in warp preparation and up to 5% higher efficiency for weaving. -

Connectivity, dashboard monitoring and Care Solutions packages

-

PROACTIVE® warping ensures enhanced quality by self-learning algorithm

WATCH OUR VIDEO AND LEARN MORE ABOUT THE PROWARP®

Our machine is suitable for processing all kinds of materials and equipped with the latest quality control, measuring & communication technologies. The PROWARP® achieves best warp quality, thanks to our proactive warping system, a cloud/server-based self-learning technology.

PROACTIVE® warping - QM solution

The selectable, innovative solutions offered by the PROWARP® configuration include PROACTIVE® warping, a system for optimising warp beam quality that will be cloud-based in the future. The new development comprises a total of three levels and amount of information increases with each one.

![]() Level 1

Level 1

Provides protocols with data on warping or beaming quality.

![]() Level 2

Level 2

Supplement of the protocols from level 1 by active quality management with a customer defined star rating.

Offers the possibility of integrating a modern high-resolution camera system. The innovative solution records measurement including the band width and band set-up – i.e. the distance from band to band or to the cone.

![]() Level 3

Level 3

Offers evaluations and diagrams for the single thread tensions of the optional MULTIGUARD yarn stop motion.

In levels 2 and 3, the data is also exchanged with the KM.ON cloud via the KM.ON device k.ey. Using cloud networking, a real-time machine dashboard can be created and, in future, it can be synchronised with new start parameters via an algorithm.

KEY BENEFITS of QM-2 (QM-3)

- Quality ratings and KPI weights fully customizable, including specific yarn-type settings

- Production KPI widely comparable, due to international manufacturing operations standard (ISO 22400-2)

- Integrated storage and searchable database for all of your reports

- Content of reports customizable according to your needs

- Easy access of database and reports via browser

- Reports exportable as PDF and MS-Office files

- Multi-machine capable (Just one server needed)

- Camera integration possible (Extension of the report with the parameters band width and band position)

INVEST INTO THE BEST EQUIPMENT AND GET THE BEST OUTPUT FROM IT

The moment you invest into the PROWARP®, KARL MAYER will guide you through all necessary know-how and training, in order to ensure your success. This in-depth training will guarantee your staff to get off to a productive start with your PROWARP® and set you up for long term success.

- Customizable onsite training

- Teleservice for every machine

What customers have to say about PROWARP®

"The PROWARP is working at highest production and produces high quality warp beams, enabling the successful performance of our weaving machines”

"The PROWARP is working at highest production and produces high quality warp beams, enabling the successful performance of our weaving machines”

"The machine ensures maximum safety and has a state-of-the-art control system.”

"The machine ensures maximum safety and has a state-of-the-art control system.”

“For us it is important to pay attention to the ergonomics of a machine and to offer only the best for our employees. In my opinion, it is always worth investing in high-quality ergonomics, which PROWARP ensures us.”

“For us it is important to pay attention to the ergonomics of a machine and to offer only the best for our employees. In my opinion, it is always worth investing in high-quality ergonomics, which PROWARP ensures us.”

"Excellent downtime performance”

"Excellent downtime performance”

"Machine operation must be simple. Machine control is about making the operation of complex machines as simple as possible. The big challenge is to reduce complexity for the operator. This is exactly what the PROWARP can offer us, which is why we are very satisfied with the machine.“

"Machine operation must be simple. Machine control is about making the operation of complex machines as simple as possible. The big challenge is to reduce complexity for the operator. This is exactly what the PROWARP can offer us, which is why we are very satisfied with the machine.“

WEBSHOP AND SPARE PARTS EMERGENCY STOCK

When investing in a PROWARP®, you are investing into the machine with the longest life time in the market. For you to produce efficiently and productively, we ensure availability and fast delivery of spare parts, to encourage your competitivity in the market and meet your customer demands.

Virtual order, real benefit – easy ordering of selected spare parts with just one mouse click. KARL MAYER‘s B2B platform WEBSHOP SPARE PARTS ensures an easy and rapid access to wearing parts and to standard spare parts.

Click here and find out more about the WEBSHOP SPARE PARTS

SECTIONAL WARPERS made by KARL MAYER

Next to the PROWARP®, KARL MAYER offers a wide range of manufacturing production warps for weaving with colour repeats for high-quality colour-woven fabrics or grey woven articles.

Explore more about SECTIONAL WARPERS