Pattern Drive

For Precision, Efficiency and High Productivity

The Continious Development of our Pattern Drives

Patterning mechanisms realize the designed patterns by driving the lateral motion of the guide bars. The struggle for more flexibility in the face of increasing productivity demands has seen the development of several technologies over the years. The sum unit replaced chain links in 1982 with the launch of the MRE-56. In 1990 the EL pattern drive had its premiere on a KS-4 and replaced in 2002 the sum unit also for lace machines.

Since then, the pattern drive technologies have been optimized continuously to guarantee precise, cost-efficient patterning at high productivity.

At KARL MAYER, we implement the following pattern drives in our machines:

- ON & EL-Drive

- N-Drive

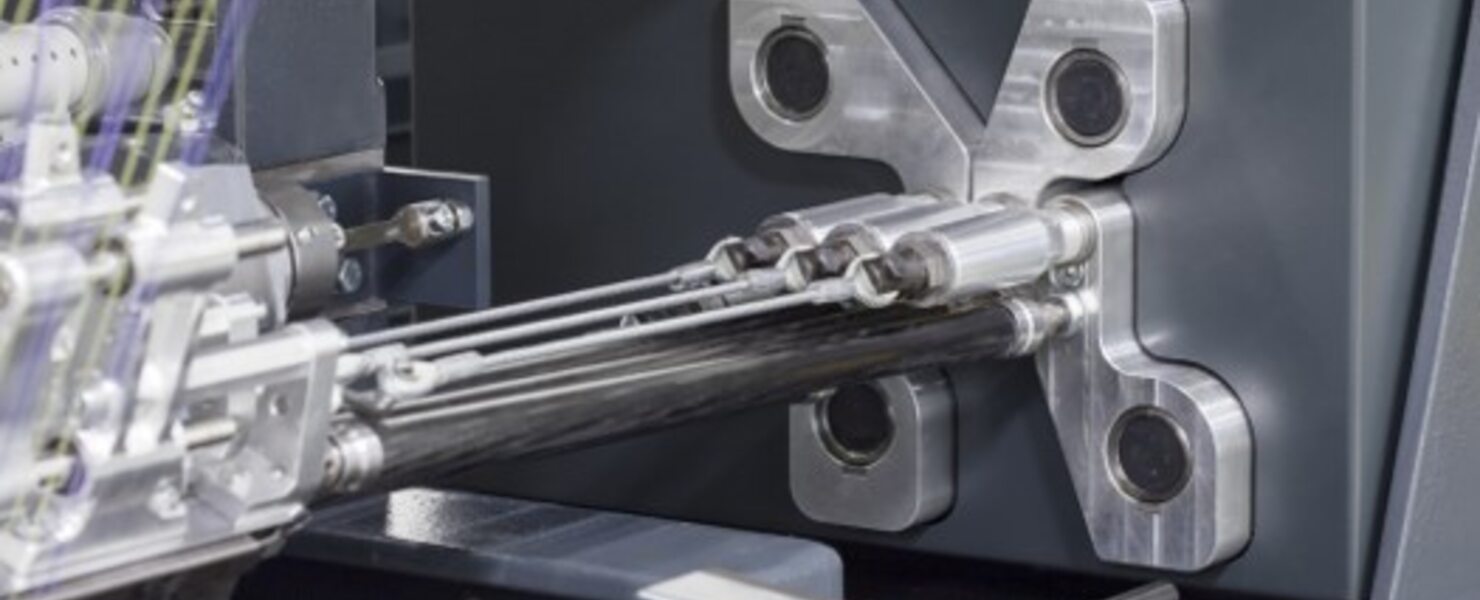

ON & EL Pattern Drive

Precise and high-speed electromechanical control of the patterning in a compact design. Allows fast pattern changes without the necessity of a cam disc stock.

ADVANTAGES OF THE ON-DRIVE

The ON-drive offers the following advantages:

-

High Productivity

High ProductivityHigh productivity on wide machines at the highest machine speeds

-

Patterning

Patterning Easy and quick pattern change

-

The Spring Motion Assistant allows a quick, easy and safe change of guide bars without tools. Spring Motion Assistant

Spring Motion Assistant

-

High flexibility in patterning through our patterning possibilities Flexibility

Flexibility -

Reduced Noise

Reduced Noise Smooth running of the bars

N- PATTERN DRIVE

A classic and fully mechanical control for production machines and suitable for rare pattern changes.

Advantages of the N-Drive

- Cost effective

- High precision

- Important for mass production