15 – k.innovation CREATE & CREATE PLUS

Digital solutions for designers & knitting technicians – by STOLL & KM.ON

- Shape library with templates for various types of products and knitting pre-sets

- Customisation of measurements to fit your product requirements

- Easy grading for additional sizes

- Option to import DXF shapes from other software or export yours for external use

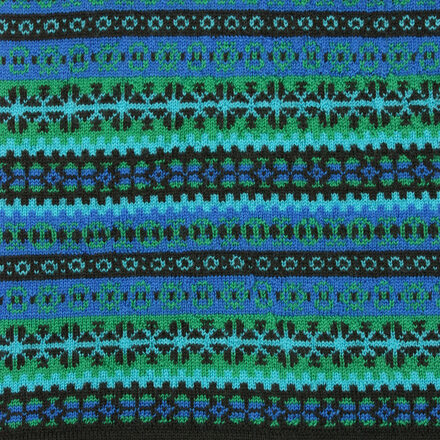

- Browse for stitch inspiration in the integrated stitch library

- Create own digital stitches with simultaneous stitch simulation

- Use the integrated stitch distortion function to preview the realistic outcome of structures and artworks

- Generate, preview and save different colourways with your seasonal yarns and colours

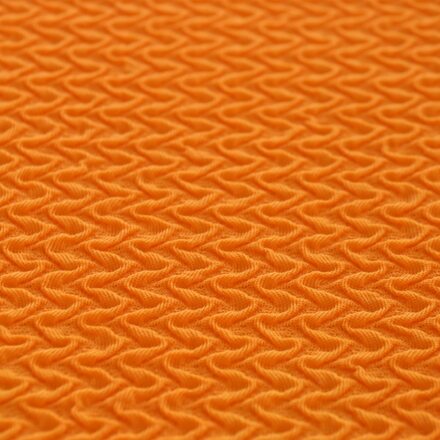

- Yarn library with standard and effect yarns that will be constantly expanded

- Creation of own yarns based on optical parameters

- Easy adjustments of yarn properties and optic

- Float Jacquard Check – to check the maximum length of 1 inch for the floats

- Stoll-ikat Plating Check – to check the minimum 2 inch distance between colour fields in one row

- Intarsia Check – to check the number of yarn carriers used in the design

- Integrated library with different jacquard types

- Easy generation of jacquard patterns

- Option to export front and back side of the jacquard

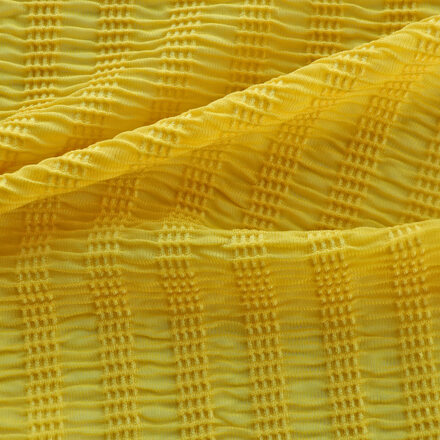

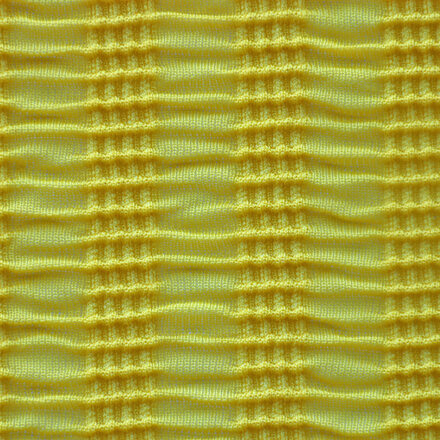

- DXF vector shapes can be sewn together to create a virtual garment

- Stitch simulations images with stitch distortion and digital yarns

- Texture maps for realistic knitwear simulation, e.g. alpha map, normal map and displacement map

-

Videos – CREATE

Videos – CREATE

-

Videos – CREATE PLUS

Videos – CREATE PLUS

-

Book Your Webinar

Book Your Webinar

-

Contacts

Contacts

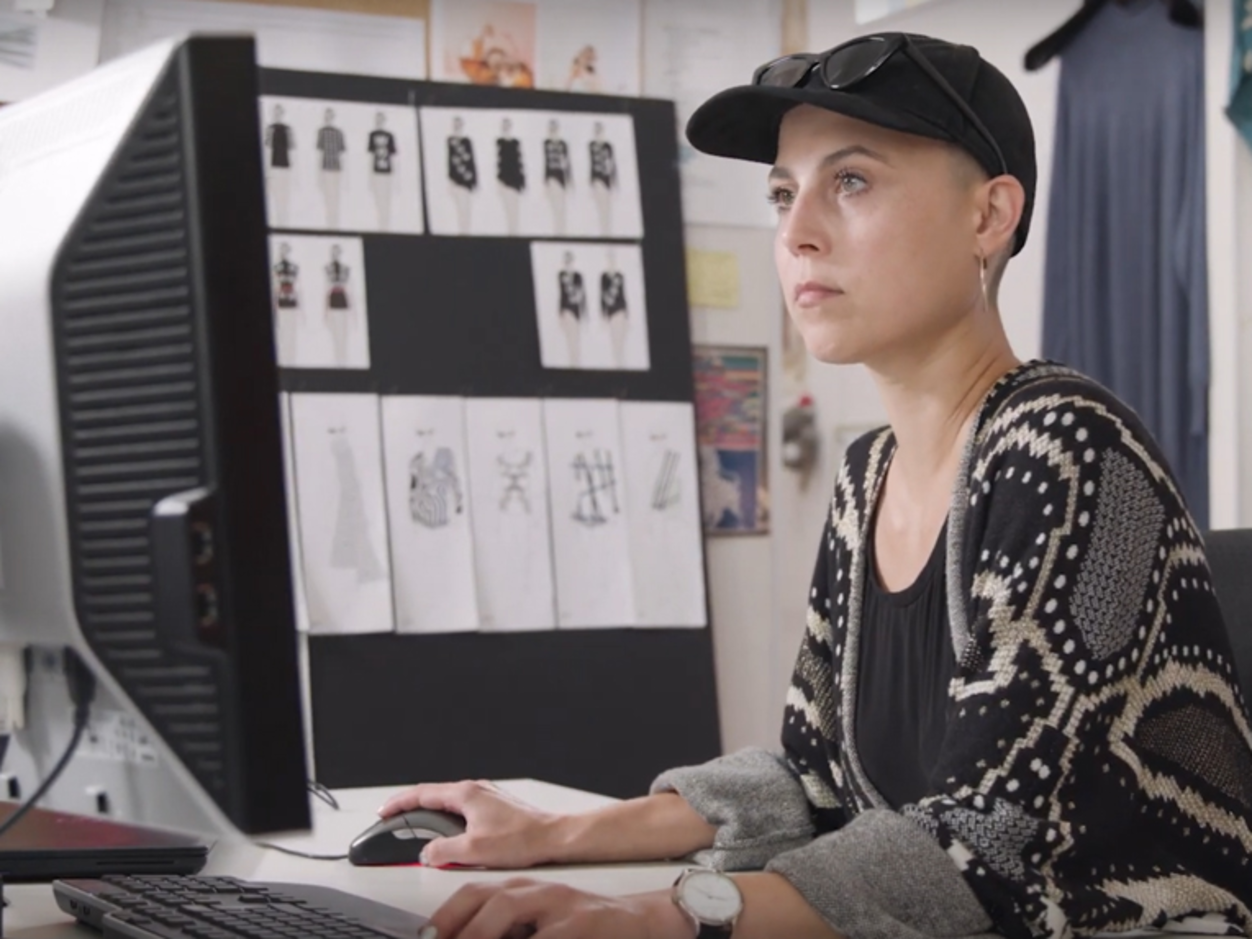

CREATE – AN INNOVATIVE TOOL FOR KNITWEAR DESIGNERS

Innovation for your creative process

CREATE KEY FEATURES

SHAPE CREATION AND GRADING

The integrated shape and grading tool assists you in the creation and customisation of knitwear shapes.

DIGITAL STITCH DEVELOPMENT

Digital design means endless possibilities. CREATE supports you through the whole design and stitch development process.

DIGITAL YARN CREATION

With the digital yarn creation you can try different types and colours of yarns without the need of scanning the.

TECHNICAL CHECKS

Access technical checks and reduce the iteration cycle with your supplier for artwork approval.

JACQUARD GENERATOR

Convert your artworks in various jacquard with the jacquard generator.

EXPORT FOR 3D

Shapes and images from CREATE can be exported for use in simulation in any 3D software:

Learn more about it on the STOLL website: More about CREATE

CREATE PLUS – A FULLY ADVANCED PROGRAMMING SYSTEM FOR KNITTING TECHNICIANS

Welcome to the world of connectivity

CREATE PLUS – Making pattern adjustments

CREATE PLUS – Creating patterns with several sizes

CREATE PLUS – Inserting an individual basic pattern in all sizes

CREATE PLUS – Simplified & fast grading

CREATE PLUS – Intelligent features & authentic fabric views

CREATE PLUS – Ability to process the entire knitting orders in few steps

BOOK YOUR WEBINAR

Join this webinar to learn more about the brand new design software for flat knitted fabrics by STOLL and KM.ON. CREATE is a powerful tool that connects knitwear design with 3D product development and knit production.

WEBINAR DATES:

08.07.2021 - 09:00 - 10:00 Uhr (CEST)

>> Registration

14.07.2021 - 15:00 - 16:00 Uhr (CEST)

>> Registration

SPEAKERS:

Goran Sidjimovski and Ellen Judith Müller

Contacts

Contact

Sandra Peixoto

Portfolio Manager Business Unit STOLLtest

- Test

test detail

Book your Webinar

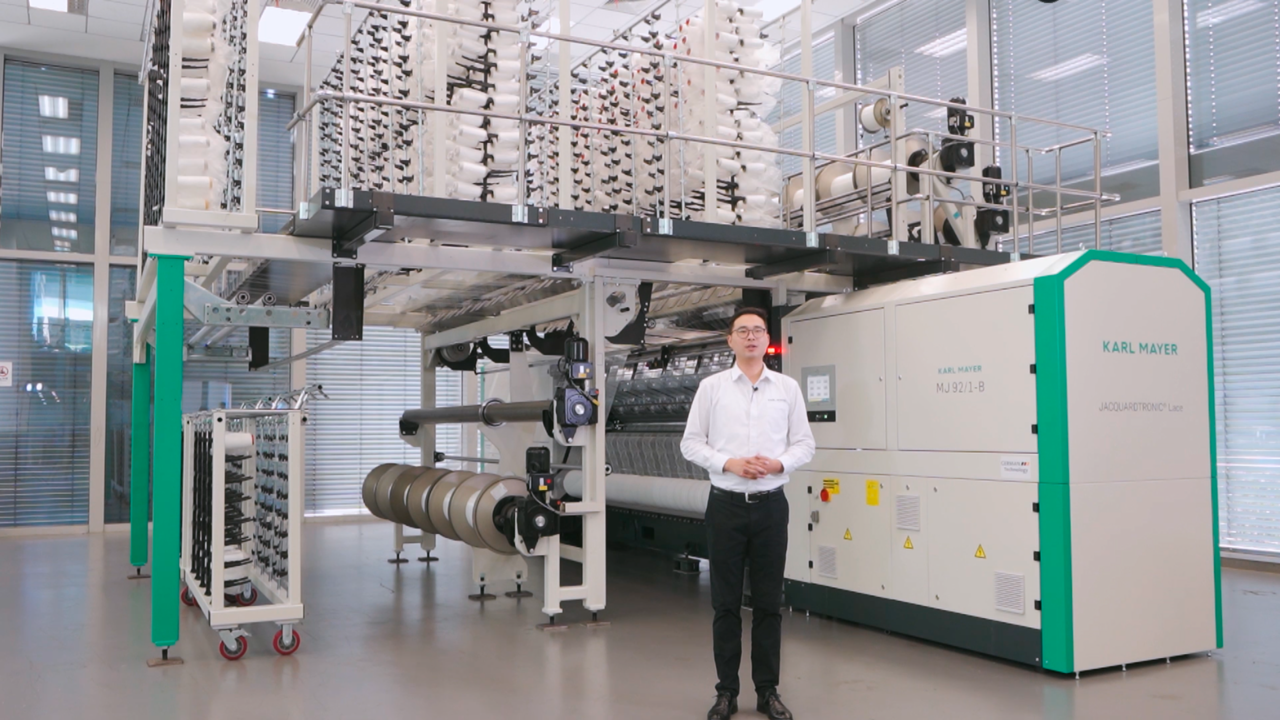

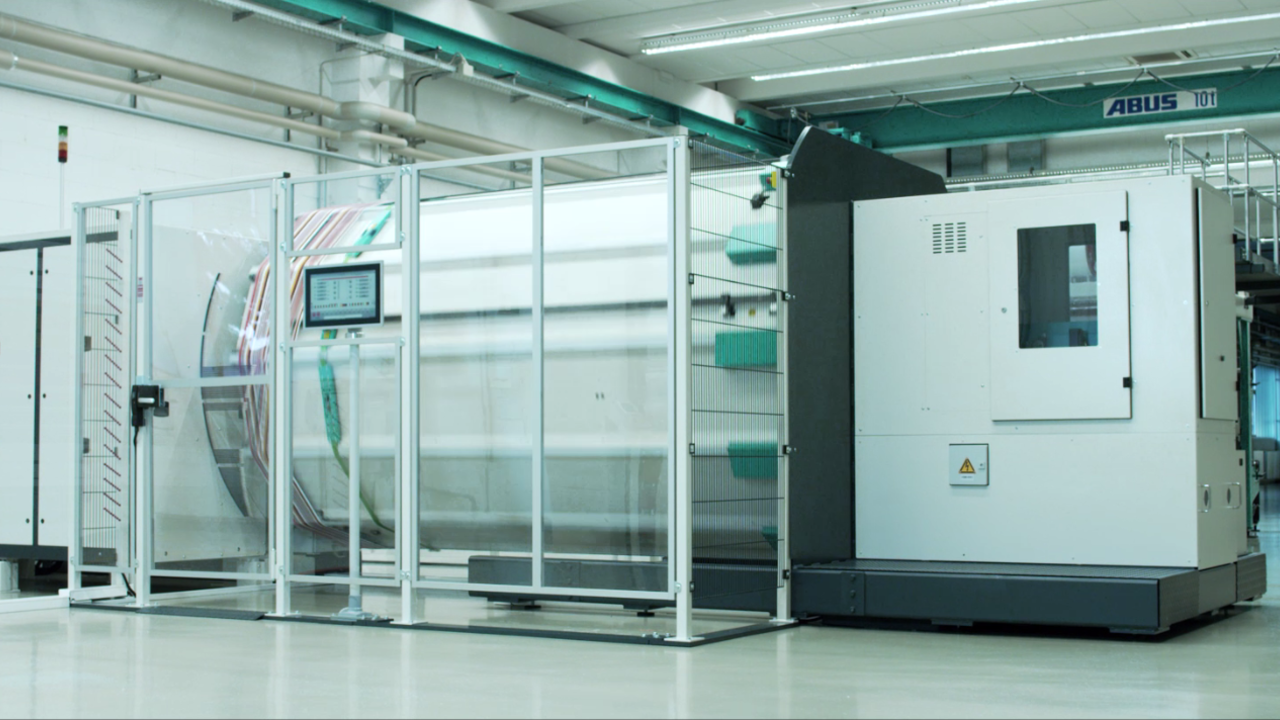

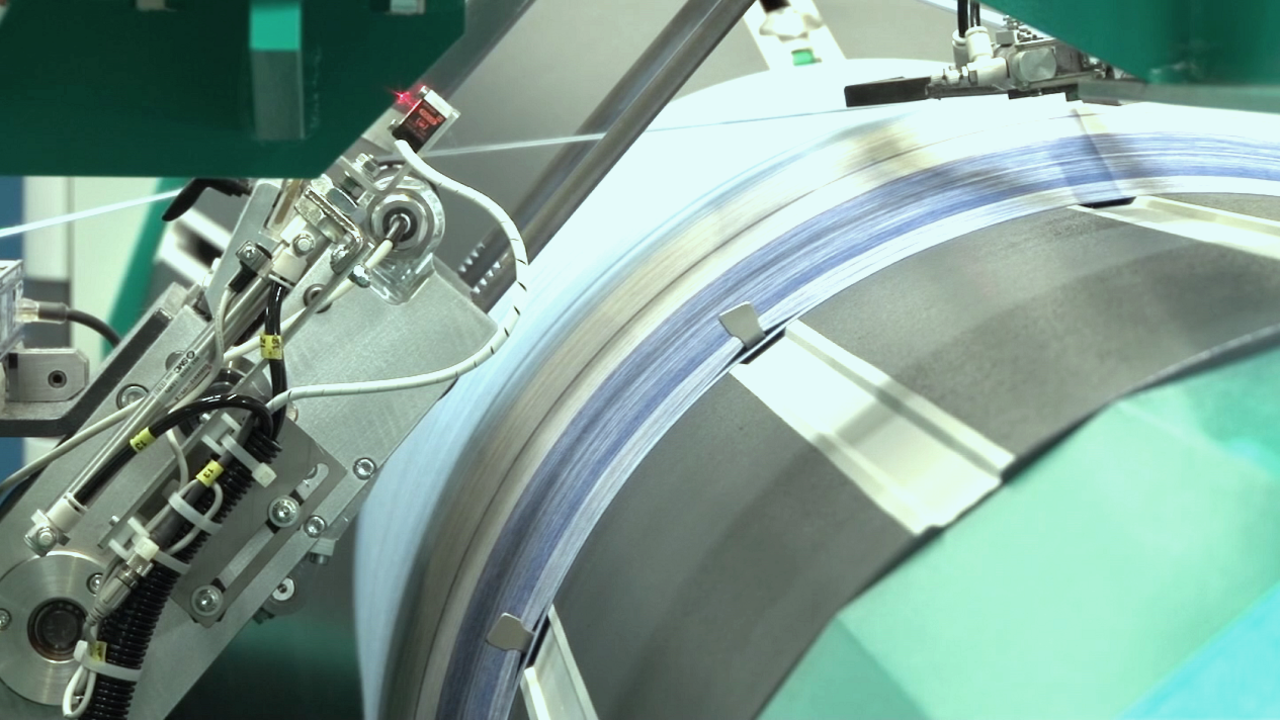

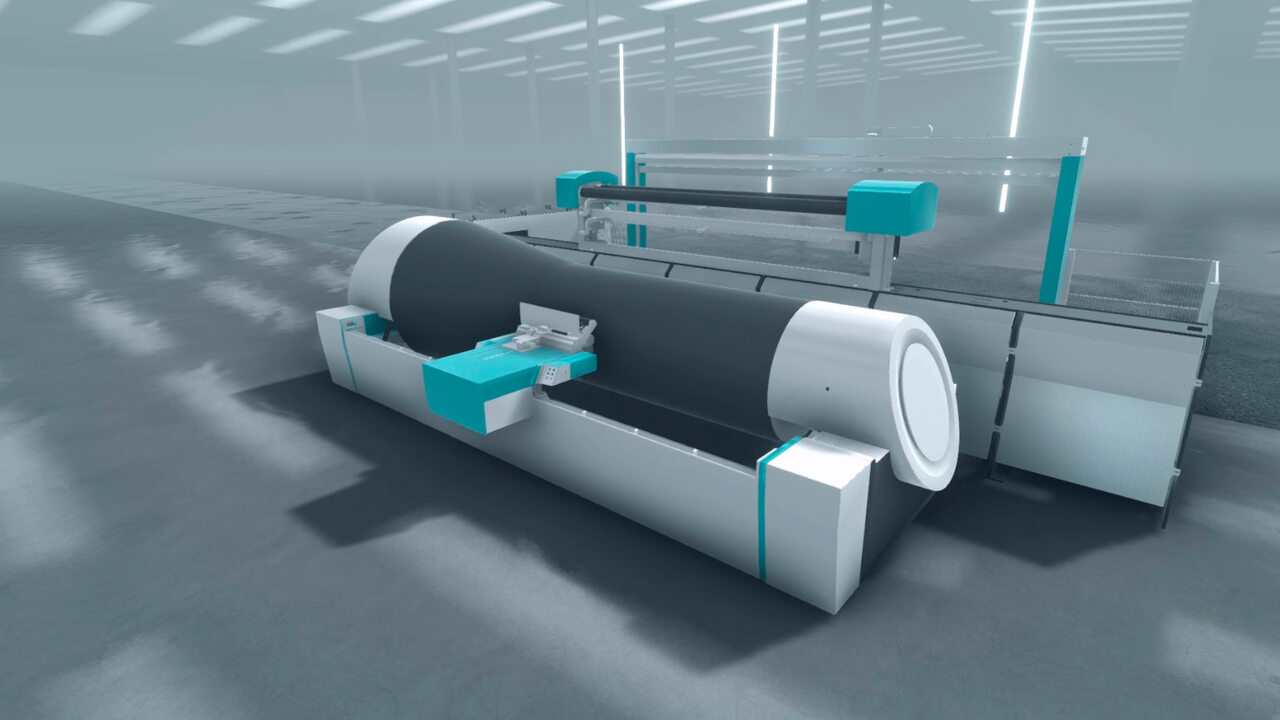

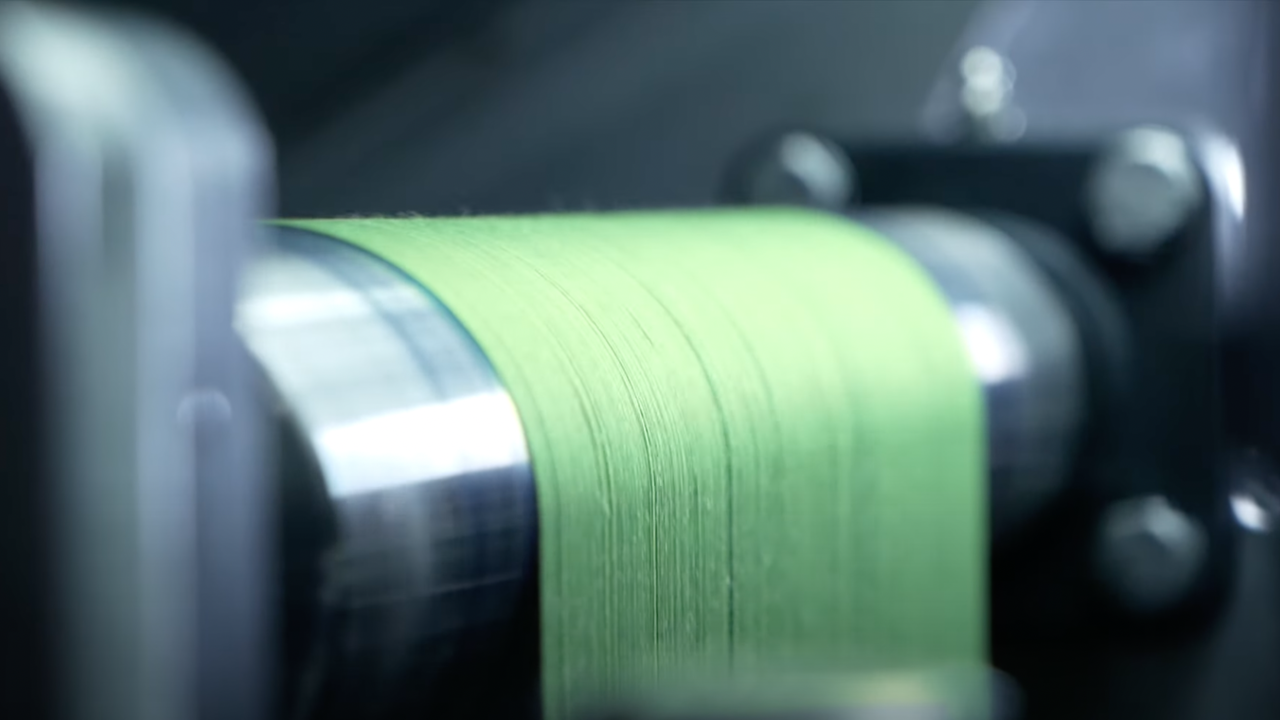

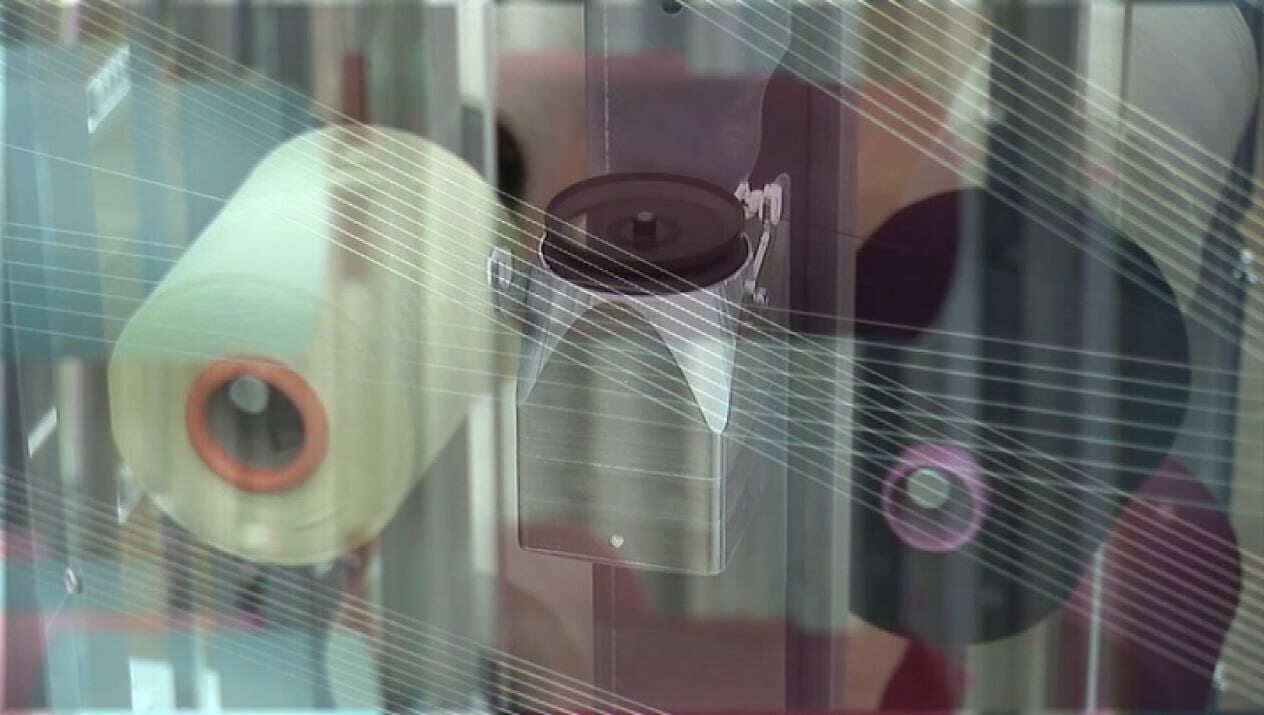

DIGITALIZATION OF WARP KNIT MACHINERY

Explore new patterning possibilities in the context of digitalization of warp knit machinery

By introducing the HKS 3-M ON as first Tricot machine with a digital business model for the change of patterns, KARL MAYER sets an important signal for the future of digitalization of warp knitting machines. SwapKnit is the first of many futured smart machine functions, that supports you to operate your machines more flexible and comfortable and to improve processes and quality in your workshop.

Webinar Dates:

23.02.2022 / 15:30-16:30 Uhr (CET)

>> Register now

24.02.2022 / 08:30-09:30 Uhr (CET)

>> Register now

Target group:

All customers and persons interested in digitalization in warp knitting

SPEAKERS:

Kay Hilbert

Product Owner Global Tricot

Marion Högg

Senior Sales Manager Care Solutions

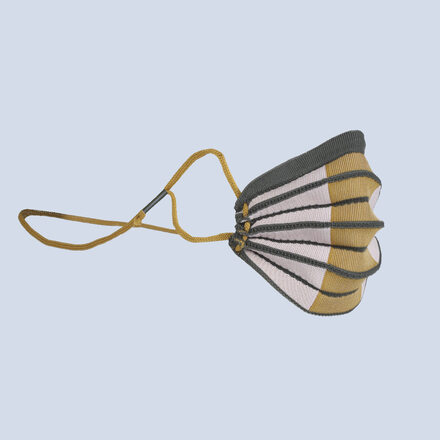

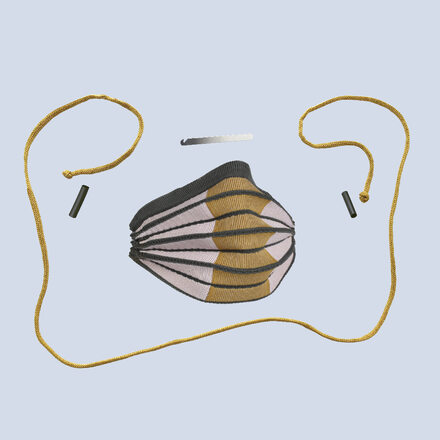

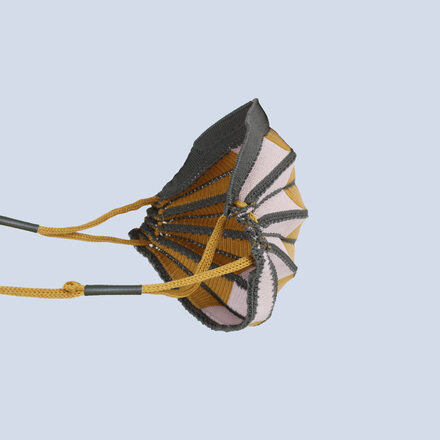

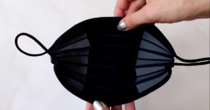

14 – Masks by STOLL

-

knitrobotik® mask

knitrobotik® mask

-

easy mask

easy mask

-

Downloads

Downloads

-

Contacts

Contacts

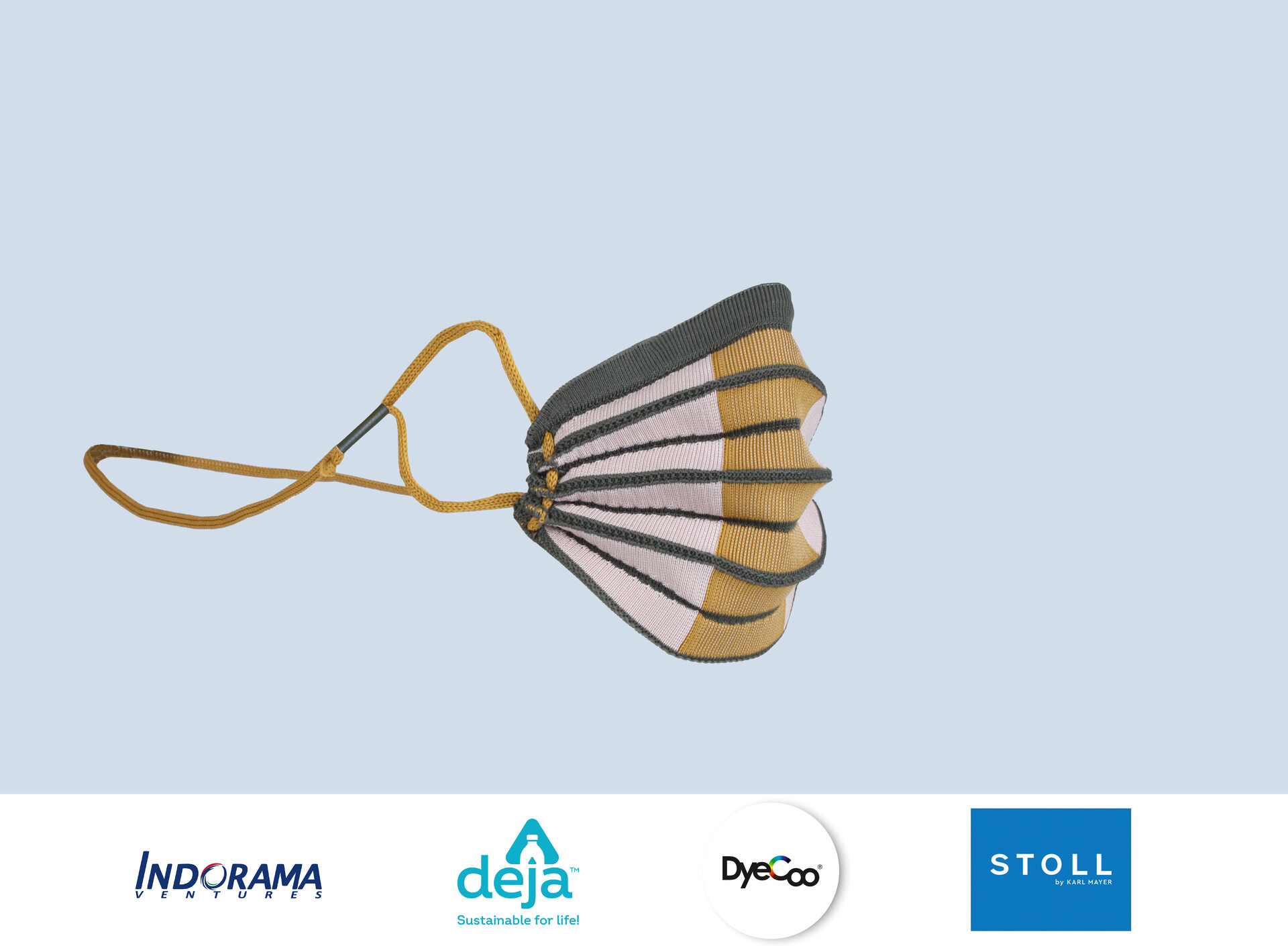

EASY MASK with smart 3D design

EASY MASK

Sustainable industry collaboration between Indorama Ventures, DyeCoo and STOLL, a brand of the KARL MAYER GROUP

EASY MASK is a collaborative initiative between Indorama Ventures, DyeCoo and STOLL to produce a fashionable mask with a sustainable mind-set throughout the whole production process - starting from the yarn production and followed by the dyeing, design and production. With the advanced technologies of the three companies, the mask does not just eliminate waste, but also reduces the use of water and energy. The design approach ensures that all components can be easily removed and re-used for other masks.

For more info please visit our website.

Downloads

Downloads

Contacts

Contact

Goran Sidjimovski

Technical Designer Business Unit STOLL13 – The Digital Future of Warp Knitting

presented by Christof Naier, President of the Business Unit Warp Knitting

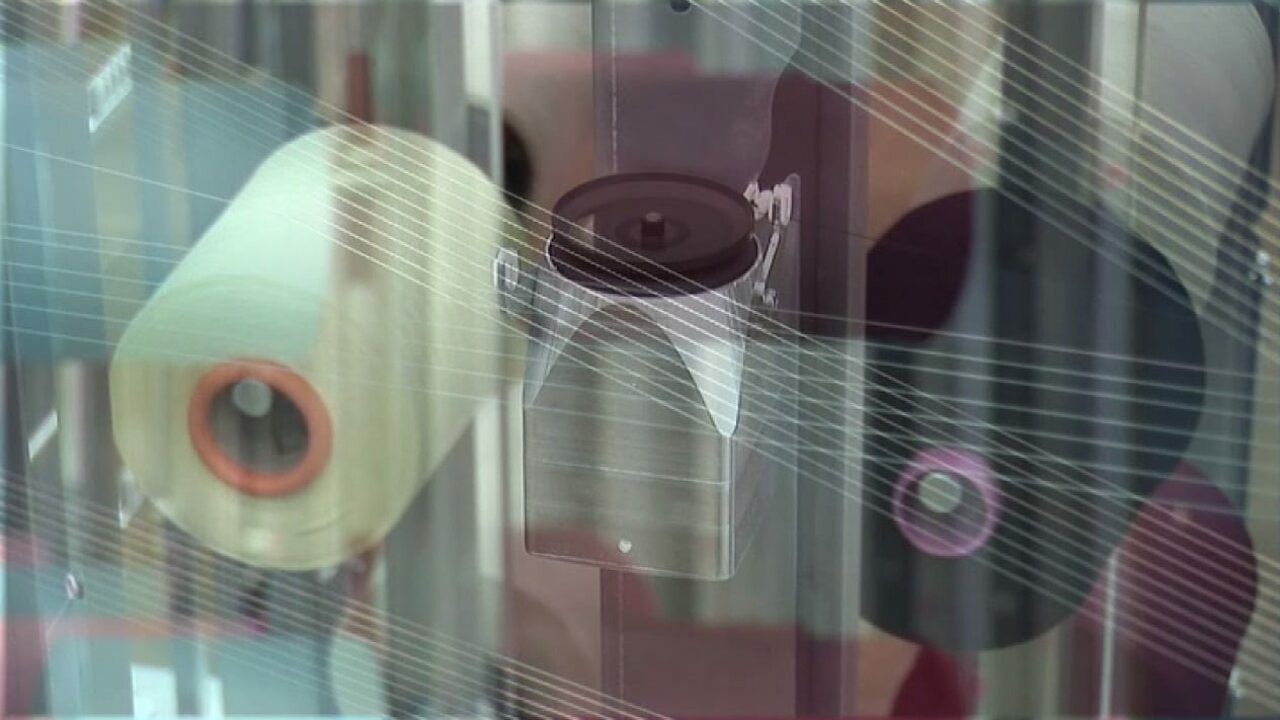

11 – Warp Preparation

Complete solutions for your success in weaving

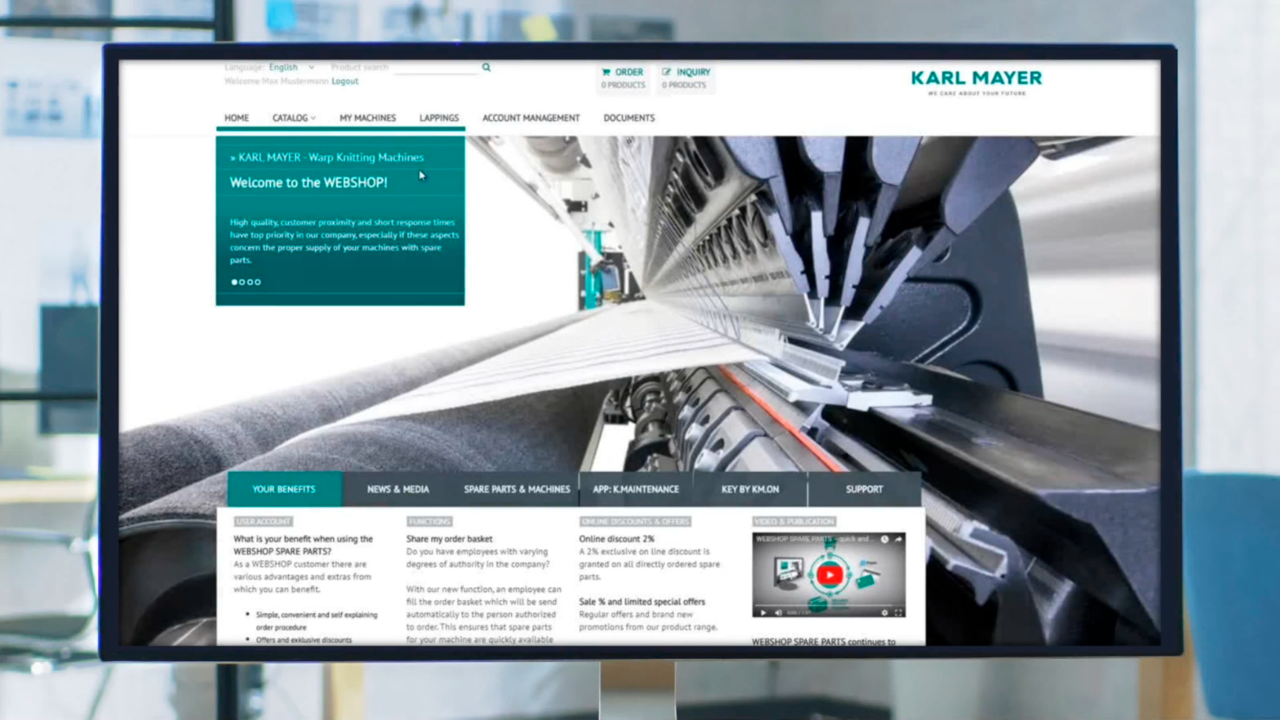

9 – Care Solutions

Experts, Parts & Online Services

Expert Interview

Our Care Solutions expert Kenny Kong in an interview on ITMA ASIA about the new after sales approach of KARL MAYER.

-

Videos

Videos

-

The minimisation of unplanned machine stops thanks to regular scheduled health checks

Optimum utilisation of machine potential thanks to expert knowledge

Reduced machine idle times thanks to remote services & spare parts support

Reduction of waste thanks to material re-use related to spare parts - for improved production sustainability

-

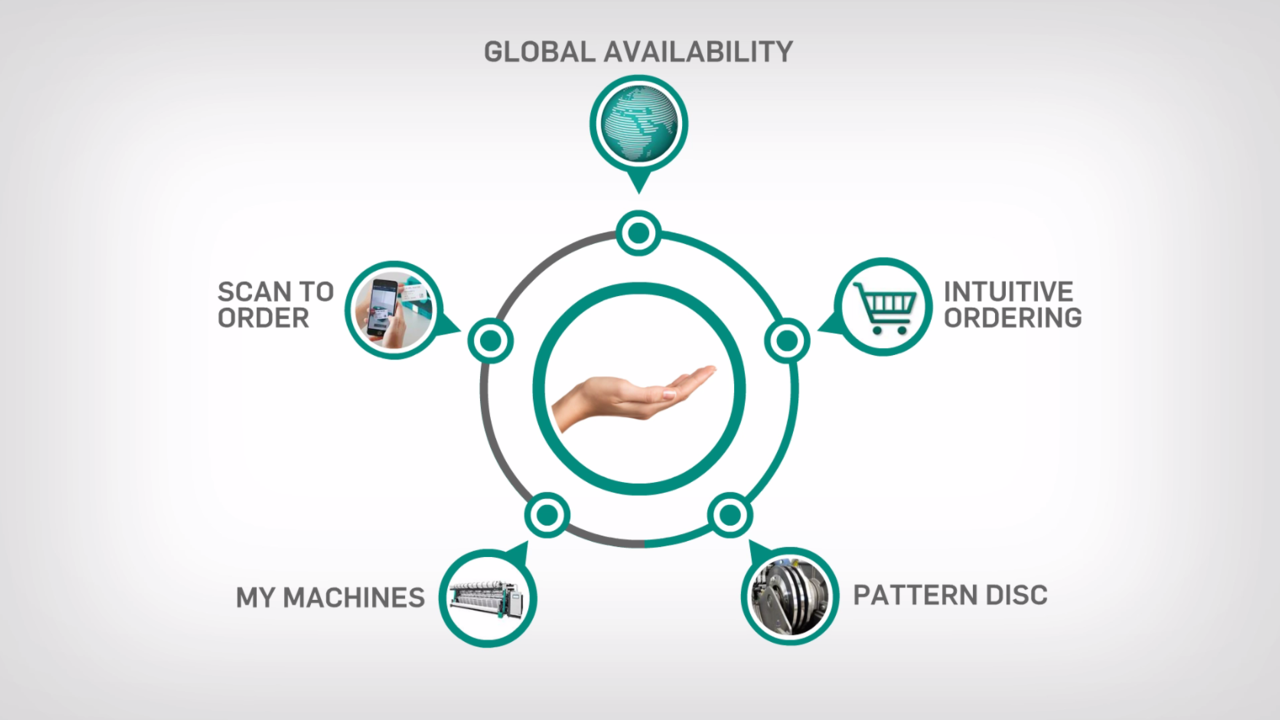

Transparent online offers for optimum planning

24/7 access to the online platform with various solutions, including our WEBSHOP

- Offer to Order function

- Delivery status tracking

- “My Parts list” for easy reordering

-

More Information

More Information

-

Contacts

Contacts

VIDEOS

Care Solutions Remote Installation (EN / CN)

How to order lappings via our WEBSHOP & SwapKnit flatrates

WEBSHOP SPARE PARTS – quick and easy access to wear & tear parts and to standard spare parts

Care Solutions

Expert knowledge, a reliable spare parts supply and online services are our contribution to your success.

We offer tailor-made packages that combine spare parts supply, service support and warp knitting expertise. Complemented by the possibilities offered through digitalisation, we take after-sales care to a new level.

A globally networked team with many years of experience in textile machinery and warp knitting processes is available to answer any warp knitting machine related questions.

We will also support you at any time with our in-depth knowledge about the mechanical and electrical components of our machines. Easy, prompt and targeted communication is important to us. This is made possible by our online platform, where you can access specific Care Solutions products or ask or book individual support.

To use all of our various online offers, machines must be connected to our network through k.ey.

Your Benefits:

Experts

Our experts are happy to help.

Our competent KARL MAYER employees with many years of experience will support you and your team when it comes to machine handling, maintenance and textile development. We always take your specific requirements into account.

You are also welcome to use the training options provided by our Academies. Our worldwide KARL MAYER Academies are excellently equipped with modern teaching materials, sample collections and training machines.

Parts

Order spare parts quickly and conveniently.

Quality, close proximity to our customers and fast response times are our priorities, especially when it comes to a reliable spare parts supply for your machine.

Order virtually and benefit in real life - simply order your spare parts via click. Thanks to its comprehensive features, our WEBSHOP makes it easy to access spare parts.

NEW! WEBSHOP - More functions available

Online Services

Our online solutions - a completely new level of after-sales support

Customer Portal “myKM.ON”

Designed to provide you with an easy-to-use platform for accessing your account information and managing your services.

E-Learning modules

Designed to give you an individual learning program anytime & anywhere.

Remote Service - reduce overall costs

Eliminating the need for on-site visits, remote support allows technicians to speed up the resolution process and minimize your machine downtime.

>> Learn more about digital products and services

>> Video tutorials

Contacts

Contact

Marion Hoegg

Senior Sales Manager Care Solutions KARL MAYER STOLL Textilmaschinenfabrik GmbHContact

Alan Garrity

Senior Sales Manager Care Solutions Business Unit WARP KNITTINGContact

Helmut Höglinger

Vice President Service Business Unit WARP KNITTINGContact

Zhen Kong (Kenny)

Chief of Care Solutions Business Unit WARP KNITTING1 – Welcome

Come with us on a quick tour over the booth of the KARL MAYER GROUP. Our moderator Lu Weiyi will guide you to our exhibition highlights of this year's ITMA ASIA. Enjoy the show!

KARL MAYER @ ITMA ASIA – presented by Lu Weiyi

-

Overview Highlights

Overview Highlights

-

Picture Gallery

Picture Gallery

-

Webinars

Webinars

-

Contacts

Contacts

Overview of Exhibition Higlights

| 1 | Welcome |

|---|---|

| 2 | KM.ON |

| 3 | BMS 52 |

| 4 | ADF 330 |

| 5 | ADF 830 |

| 6 | FASTER: FROM (CONCEPT) - TO (STORE) |

| 7 | Textiles in Infrastructure, Building and Construction |

| 8 | HKS 3-M ON |

| 9 | Care Solutions |

| 10 | Smart Casual Warp Knits |

| 11 | Warp Preparation |

| 12 | Sustainable Denim |

| 13 | The Digital Future of Warp Knitting |

| 14 | Masks by STOLL |

| 15 | k.innovation CREATE & CREATE PLUS |

Picture Gallery

Click to expand the pictures.

Book your Webinar

DIGITALIZATION OF WARP KNIT MACHINERY

Explore new patterning possibilities in the context of digitalization of warp knit machinery

By introducing the HKS 3-M ON as first Tricot machine with a digital business model for the change of patterns, KARL MAYER sets an important signal for the future of digitalization of warp knitting machines. SwapKnit is the first of many futured smart machine functions, that supports you to operate your machines more flexible and comfortable and to improve processes and quality in your workshop.

Webinar Dates:

23.02.2022 / 15:30-16:30 Uhr (CET)

>> Register now

24.02.2022 / 08:30-09:30 Uhr (CET)

>> Register now

Target group:

All customers and persons interested in digitalization in warp knitting

SPEAKERS:

Kay Hilbert

Product Owner Global Tricot

Marion Högg

Senior Sales Manager Care Solutions

Contacts

Contact

Contact

Christine Wolters

Head of Corporate Communications Corproate Communications7 – Textiles in Infrastructure, Building and Constructions

Civil engineering business undergoes a radical change and is in search of innovative solutions with high efficiency and low resource consumption. KARL MAYER Technical Textiles can be the solution. Watch the video now, to learn all about it!

Textiles in civil engineering – Benefit from rethinking!

-

Machine videos

Machine videos

-

Downloads

Downloads

-

Contacts

Contacts

Brochures & Factsheets

Contacts

Contact

Erik Junghans

Sales Manager Asia Business Unit Technical TextilesContact

Jan Stahr

Sales Manager China Business Unit Technical TextilesContact

Lutz Heinig

Sales Manager Americas Business Unit Technical TextilesContact

Hagen Lotzmann

VP Sales Business Unit Technical TextilesContact

Frank Felgner

Sales Manager Western Europe Business Unit Technical TextilesContact

Naci Oguzlu

Sales Manager Middle East / Africa Business Unit Technical TextilesContact

Ralf Schramm

Sales Manager Eastern Europe Business Unit Technical Textiles12 – Sustainable Denim

The most sustainable and profitable way to make denim

GREENDYE - Indigo dying range in nitrogen atmosphere

-

Fabric Gallery

Fabric Gallery

-

Book your Webinar

Book your Webinar

-

Contacts

Contacts

Sustainable Denim Gallery

Sustainable Denim N°001

Sustainable Denim N°001

Scouring & Pure Indigo / 预处理及纯靛蓝染色

| Oz / 盎司 | Twill / 斜纹 | Indigo / 上色率 [%] |

| 9,5 | 2.1 | 1,7% |

Sustainable Denim N°002

Sustainable Denim N°002

Scouring & Pure Indigo / 预处理及纯靛蓝染色

| Oz / 盎司 | Twill / 斜纹 | Indigo / 上色率 [%] |

| 9,5 | 2.1 | 1,9% |

Sustainable Denim N°003

Sustainable Denim N°003

Scouring & Pure Indigo / 预处理及纯靛蓝染色

| Oz / 盎司 | Twill / 斜纹 | Indigo / 上色率 [%] |

| 10,5 | 2.1 | 2,7% |

Sustainable Denim N°004

Sustainable Denim N°004

Scouring & Pure Indigo / 预处理及纯靛蓝染色

| Oz / 盎司 | Twill / 斜纹 | Indigo / 上色率 [%] |

| 10,5 | 2.1 | 2,5% |

Sustainable Denim N°005

Sustainable Denim N°005

Scouring & Pure Indigo / 预处理及纯靛蓝染色

| Oz / 盎司 | Twill / 斜纹 | Indigo / 上色率 [%] |

| 10,5 | 2.1 | 2,1% |

Sustainable Denim N°006

Sustainable Denim N°006

Scouring & Pure Indigo / 预处理及纯靛蓝染色

| Oz / 盎司 | Twill / 斜纹 | Indigo / 上色率 [%] |

| 10,5 | 2.1 | 1,5% |

Book your Webinar

Explore more about nitrogen technolgy with GREENDYE as a key factor for your success in the market. Look as you can reduce yarn waste with LINKMATIC.

Webinar Dates:

15.07.2021 - 08:00 - 08:30 Uhr (CEST)

>> Registration

15.07.2021 - 15:00 - 15:30 Uhr (CEST)

>> Registration

SPEAKER:

Stefano Agazzi

Contacts

Contact

Dieter Gager

Vice President Sales and Marketing Business Unit WARP PREPARATIONContact

Stefano Agazzi

Chief of Technology and Products Business Unit WARP PREPARATION3 – BMS 52

Flat knitting machine to produce fully fashion or cut & sew articles

Expert Interview

Our expert Liu Xuran in an interview at ITMA ASIA about the features and applications of the BMS 52, including a showcase of a baby sweater.

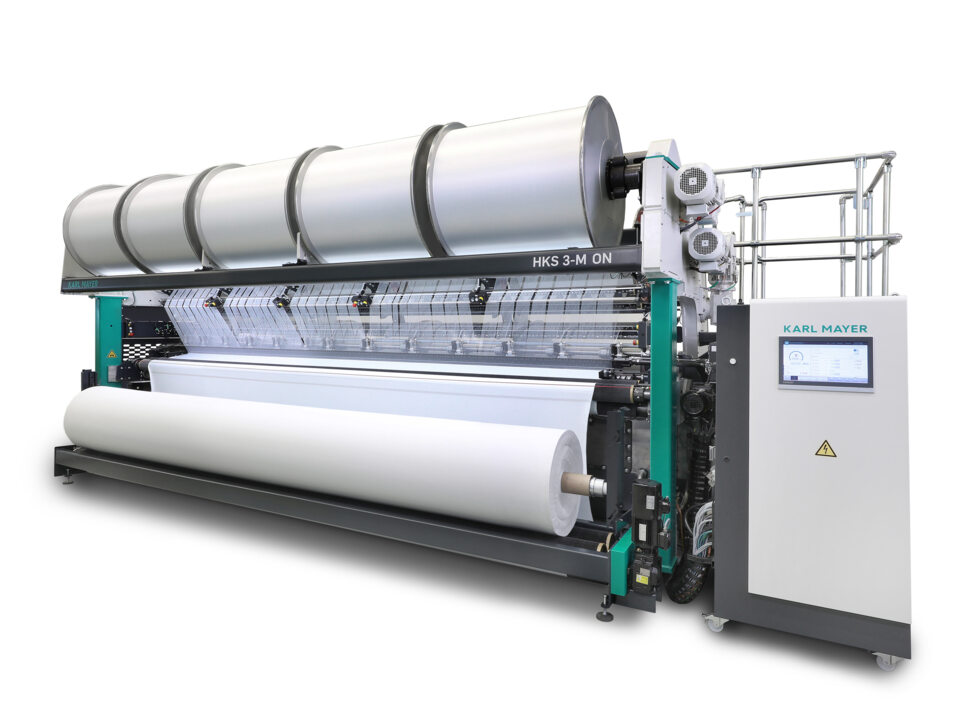

8 – HKS 3-M ON

The fastest and widest tricot machine on the market

Expert Interview

Product manager Lin Tailai and sales expert Harry Xu in an interview at ITMA ASIA about the features and application fields of the HKS 3-M ON.

- Energy Data Ready

- Reproducible sinker positioning

- Integrated camera system with transmitted light set-up

- Lights for fabric check after take-up

- Improved warp beam frame structure

- Flexible patterning possibilities

-

State-of-the-Art Technology

State-of-the-Art TechnologyThe ON-drive pattern system with unlimited repeats, energy efficient direct drive solution, and user-friendly spring motion assistant – all these innovative features increase the efficiency of your production

-

Optimized Costs & Improved Sustainability

Optimized Costs & Improved SustainabilityMinimized maintenance costs and reduced energy consumption through direct drive system. Less costs for patterns compared to pattern discs

-

Quick, easy and safe change of guide bars without tools. At the push of a button the spring motion wire tension is released, and it can be removed with a simple tool such as a screwdriver Spring Motion Assistant

Spring Motion Assistant -

Prepare your business for the challenges in the modern business environment – immediate pattern change and higher productivity for a fast reaction to market demands. Maximize the effectivity of your factory space Efficient Production

Efficient Production -

Digital KARL MAYER World

Digital KARL MAYER WorldEnjoy our digital offers to connect your machines for greater flexibility and competitivity

-

Improved Machine Design

Optimised machine design for user-friendly handling. Working platform infront of the machine for easy handling of larger fabric rolls. Easy and safe access to warp beam clamping positions through moveable ladders -

- Reducing the TCO

- Energy efficiency

- Optimize maintenance costs

- Maximized factory utilization

- Reducing our carbon footprint with cloud-based solutions

- Expanding our machines capabilities towards biodegradable and other sustainable yarns

- Simplifying and automating processes to reduce expertise on the shop floor

- Flexible patterning models for all customer’s needs

- Pushing the boundaries of machine production with new technologies

- Faster and easier availability of patterns and articles

-

More Information

More Information

-

Downloads

Downloads

-

Book Your Webinar

Book Your Webinar

-

Contacts

Contacts

HKS 3-M ON

Features & Technologies

Machine Highlights

In addition to our renowned ON-technology, the HKS 3-M ON also offers the following advantages:

Master the challenges of the market with our HKS 3-M ON

PROFITABILITY & OPTIMIZED COSTS

SUSTAINABILITY & STAFFING

FLEXIBILITY & OPPORTUNITY

Purchase Articles Online

You can now download pattern data files via our webshop into your k. innovation software.

FIND YOUR PERFECT MACHINE

KARL MAYER is offering a wide range of working width for the HKS 3-M ON machines with various functions and possibilities. Please use the table below to find the suitable product for your future success.

| Machine specification | HKS 3-M ON | ||||

|---|---|---|---|---|---|

| Working width | 130“ + 4" | 180“ + 6“ | 210" + 8" | 280" + (10"/20") | |

| Gauge | E 28, E 32 | E 28, E 32 | E 28, E 32 | E 28, E 32 | |

| Warp beam support | 3x32" (Standard) | ✓ | ✓ | ✓ | ✓ |

| 3x40" (Optional) | ✓ | ✓ | ✓ | ✓ | |

| 1x40", 2x32" (Upon request) | ✓ | ✓ | ✓ | ✓ | |

| KAMCOS® 2 | Multispeed (Optional) | ✓ | ✓ | ✓ | X |

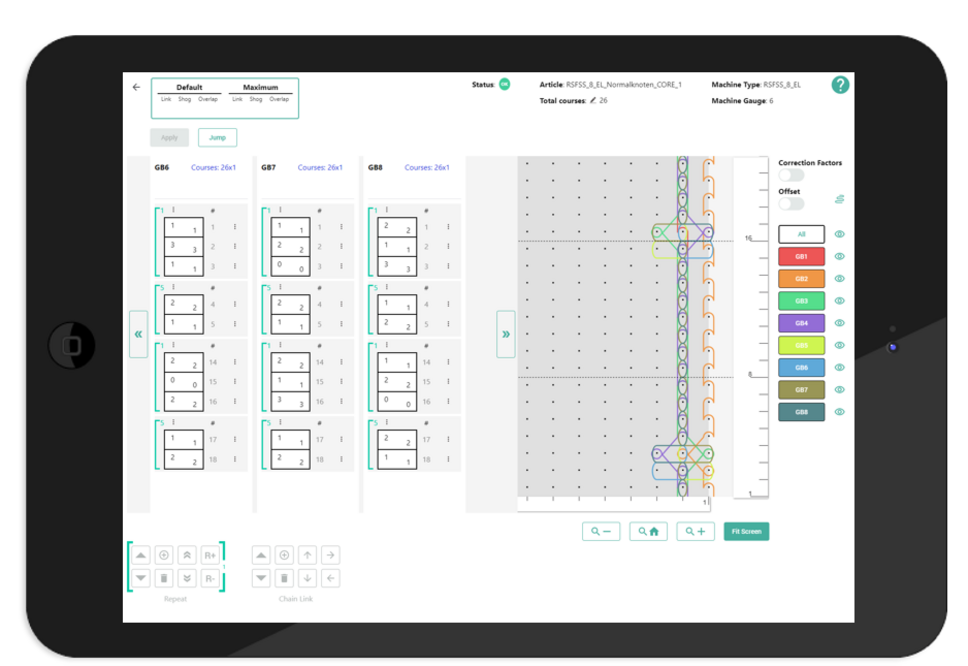

Patterning Possibilities

Enjoy the flexibility in creating patterns with our latest pattern software k.innovation CORE lite! To find out more, please click here.

Downloads

Downloads

BOOK YOUR WEBINAR

Machine Highlights, comparison between HKS 3-M to HKS 3-M ON, HKS 3-M ON 280” Important Dates and Pattern Change and Design with ON-Drive „SwapKnit“

Webinar Dates:

01.07.2021 - 09:00-10:00 Uhr (CEST)

>> Registration

01.07.2021 - 15:00-16:00 Uhr (CEST)

>> Registration

SPEAKERS:

Robert Kuna and Elisabeth Dröse

Contacts

Contact

Tailai Lin

Head of Tricot Machinery (Chinese Market) Business Unit WARP KNITTING4 – ADF 330

High-tech and multifunctional all-in-one machine to produce narrow knit & wear or multi gauge articles with intarsia, inverse/ikat plating, intarsia plating, selective plating and with weave-in device.

Expert Interview

Our expert Michael Sedlag in an interview at ITMA ASIA about the features and application fields of the ADF 330.

-

Videos

Videos

-

Downloads

Downloads

-

Contacts

Contacts

GOOD PARTNERSHIPS CREATE INNOVATION

Knitted Sensor Glove – Cooperation with Bosch

Seamless Shoe Production – Cooperation with DESMA (EN)

Seamless Shoe Production – Cooperation with DESMA (CN)

Downloads

Contacts

Contact

Sandra Peixoto

Portfolio Manager Business Unit STOLL6 – FASTER: FROM(CONCEPT) - TO(STORE)

FASTER – From(CONCEPT) To(STORE)

- Coarse-looking oversized Fully Fashion coat

- Base fabric: Inverse plated jersey transfer structure in 1x1 technique

- Coarse weft insert with varying needle set-ups

- Knitted in patch pocket with second color inverse plated pocket bag

-

Fashion Gallery

Fashion Gallery

-

Downloads

Downloads

-

Contacts

Contacts

Fashion Gallery

Fully Fashion Boxy Shirt

Fully Fashion Boxy Shirt

Re-interpretation of Stoll Pattern 1310183

机型/ machine: CMS 502 HP+ multi gauge E 3,5.2

产品号 / article: 1910079

原料/ material: 70% Cotton, 30% Polyamide

特征 / feature: Honeycomb and different pointelle structures

Running time: 32 min 19 sec

Patternsoftware: k.innovation CREATE Plus®

Basic Polo Shirt

Basic Polo Shirt

Structure inspiration from Stoll Pattern 1410034

机型/ machine: CMS 502 HP+ multi gauge E 7.2

产品号 / article: 1910062

原料/ material: 100% Cotton

特征 / feature: knitted on economic machine

Running time: 46 min 18 sec

Patternsoftware: k.innovation CREATE Plus®

Fully Fashion Slipover

Fully Fashion Slipover

Re-interpretation of Stoll Pattern 1010305

机型/ machine: CMS 502 HP+ multi gauge E 3,5.2

产品号 / article: 1910080

原料/ material: 76% Cotton, 24 % Polyamide

特征 / feature: knitted on economic machine

Running time: 37 min 34 sec

Patternsoftware: k.innovation CREATE Plus®

Fully Fashion Coat

Fully Fashion Coat

|

Pattern No. |

1910052 / http://patternshop.stoll.com |

|

Collection |

FASTER: From(CONCEPT)-To(STORE) |

|

Type |

CMS ADF 32 W multi gauge |

|

Gauge |

E7.2 |

|

Notes |

Stoll-ikat plating®, Stoll-weave-in®, Stoll-applications® From 1510033 - To 1910052 |

| Yarn |

1x Nm 1,4, Cocoon (45% WV, 30% WK, 25% PA), Lineapiù 1x Nm 2,3, Park (76% CO, 24% PA), Be.Mi.Va. 1x Nm 30/2, Cashwool (100% WV), Zegna Baruffa 1x Nm 30, Viscrepe(100% VI), Filpucci 1x Nm 50/3, kbA Baumwolle (100% CO), Gebrüder Otto 4x Nm 60, Glow (100% PES), Pinori Filati |

| Time |

1 R-piece(s) 13 min. 12 sec. @ 1.00 m/sec. 1 V-piece(s) right 17 min. 51 sec. @ 1.00 m/sec. 1 sleeve left 16 min. 51 sec. @ 1.00 m/sec. 1 sleeve right 16 min. 51 sec. @ 1.00 m/sec. 1 V-piece(s) left 17 min. 48 sec. @ 1.00 m/sec. |

Fully Fashion Men's Cardigan

Fully Fashion Men's Cardigan

|

Pattern No. |

1910060 / http://patternshop.stoll.com |

|

Collection |

FASTER: From(CONCEPT)-To(STORE) |

|

Type |

CMS ADF 32 W multi gauge |

|

Gauge |

E7.2 |

|

Notes |

Stoll-ikat plating®, Stoll-weave-in®, Stoll-applications®, Stoll-artwork® From 1510006 - To 1910060: Fully Fashion men's cardigan with knitted-in chest pocket, button placket and button holes. The jersey transfer structure is reinforced with Stoll-weave-in® yarn insert. Multiple weft insertions in the shoulder area and collar. |

| Yarn |

1x, 2x Nm 15/1, Supergeelong (100% WV), Zegna Baruffa (Chiavazza) 1x Nm 30, Viscrepe (100% VI), Filpucci 1x Nm 60/2, Millennium (100% WV), Zegna Baruffa 1x Nm 8, Roller (83% VI, 17% PA), Filpucci 4x Nm 60, Glow (100% PES), Pinori Filati |

| Time |

1 V-piece(s) left 20 min. 43 sec. @ 1.00 m/sec. 1 V-piece(s) right 21 min. 57 sec. @ 1.00 m/sec. 1 R-piece(s) 16 min. 55 sec. @ 1.00 m/sec. 1 sleeve left 1 9 min. 25 sec. @ 1.00 m/sec. 1 sleeve right 1 9 min. 24 sec. @ 1.00 m/sec. 1 collar 14 min. 02 sec. @ 1.00 m/sec. |

Fully Fashion Raglan Pullover

Fully Fashion Raglan Pullover

|

Pattern No. Muster-Nr. |

1910061 / http://patternshop.stoll.com |

|

Collection |

FASTER: From(CONCEPT)-To(STORE) |

|

Type |

ADF 530-32 W multi gauge |

|

Gauge |

E7.2 |

|

Notes |

Stoll-ikat plating®, Stoll-weave-in®, Stoll-artwork® From 1810124 - To 1910061 Fully Fashion raglan pullover with destroyed look. Different intarsia plated areas feature various weave-in yarns combined with 2-layer tuck mesh structure. |

| Yarn |

1x Nm 2,8, Azhar (100% WV), Zegna Baruffa 1x Nm 3,7, Detroit (100% PP), Sesia 1x, 2x Nm 60/2, Millennium (100% WV), Zegna Baruffa 1x Nm 60/2, K-Wool High Twisted (100% WV), Zegna Baruffa |

| Time |

1 Ärmel links 1 16 min. 39 sec. @ 1.00 m/sec. 1 R-Teil(e) 22 min. 10 sec. @ 1.00 m/sec. 1 V-Teil(e) 21 min. 33 sec. @ 1.00 m/sec. 1 Ärmel rechts 1 8 min. 0 sec. @ 1.00 m/sec. 1 Kragen_1 0 min. 42 sec. @ 1.00 m/sec. 1 Kragen_2 0 min. 53 sec. @ 1.00 m/sec. |

Wrap Skirt

Wrap Skirt

|

Pattern No. |

1910063 / http://patternshop.stoll.com |

|

Collection |

FASTER: From(CONCEPT)-To(STORE) |

|

Type |

ADF 530-32 W multi gauge |

|

Gauge |

E7.2 |

|

Notes |

Stoll-weave-in®, Stoll-artwork® From 1810124 - To 1910063 Wrap skirt with 2-layer tuck mesh structure rows with differnet needle set-up for Stoll-weave-in®. The intarsia jersey structure consists of different yarns, plated with synthetic material, wool and silk for a good skin feel. Skirt is gored to the body shape and reinforced with thermoplastic yarn. |

| Yarn |

1x dtex 167 f34, Grilon KE-60 (CO-POLYESTER), EMS-Griltech 1x dtex 76 f24 x1, Diolen® text. SET trilobal (100% PES), TWD Fibres 1x Nm 1,7, Corda (100% PES), Igea 1x Nm 4,2, Roller (83% VI, 17% PA), Filpucci 1x Nm 4,8, Topgum (100% PA), Be.Mi.Va. 1x Nm 60/2, Angel (100% SE), Sesia 1x Nm 60/2, K-Wool High Twisted (100% WV), Zegna Baruffa 1x Nm 9, Diver (100% PA), Be.Mi.Va. |

| Time | 1 Leibteil(e) 62 min. 34 sec. @ 1.00 m/sec. |

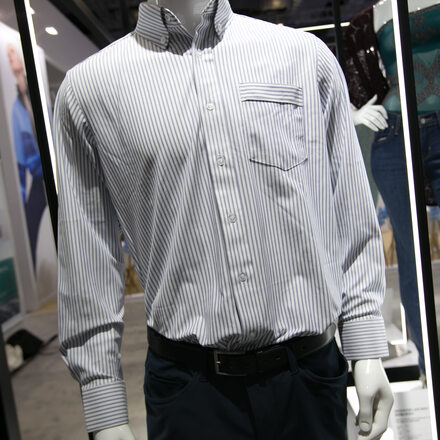

Fully Fashion Long Sleeve Polo Shirt

Fully Fashion Long Sleeve Polo Shirt

|

Pattern No. |

1910075 / http://patternshop.stoll.com |

|

Collection |

FASTER: From(CONCEPT)-To(STORE) |

|

Type |

CMS ADF 32 BW |

|

Gauge |

E18m.16 |

|

Notes |

Stoll-ikat plating® From 1410034 - To 1910075 Fully Fashion long-sleeve polo shirt in plated multi-colour piqué structure. Stoll knitelligence® software package with Stoll-autocreate® in combination with Stoll-artwork® enables automated production. |

| Yarn |

1x, 2x Nm 90/2, Suvin merc. (100% CO), Emilcotoni |

| Time |

1 R-Teil(e) 17 min. 7 sec. @ 1.00 m/sec. 1 Zutaten_1 4 min. 46 sec. @ 1.00 m/sec. 1 Kragen_1 10 min. 0 sec. @ 0.75 m/sec. 1 Ärmel links 1 12 min. 30 sec. @ 1.00 m/sec. 1 Ärmel rechts 1 12 min. 23 sec. @ 1.00 m/sec. 1 V-Teil(e) 19 min. 35 sec. @ 1.00 m/sec. |

Fully Fashion Crop Top

Fully Fashion Crop Top

|

Pattern No. |

1910078 / http://patternshop.stoll.com |

|

Collection |

FASTER: From(CONCEPT)-To(STORE) |

|

Type |

ADF 530-32 W multi gauge |

|

Gauge |

E7.2 |

|

Notes |

Stoll-weave-in®, Stoll-artwork® From 1810124 - To 1910078 Gored Fully Fashion crop top with 2-layer tuck mesh structure rows with differnet needle set-up for Stoll-weave-in®. The intarsia jersey structure consists of diffrent yarns, plated with synthetic material, wool and silk for a good skin feel. The one-piece top is shaped directly in the knitting process. The cups are additionally moulded with melting yarn. |

| Yarn |

1x dtex 167 f34, Grilon KE-60 (CO-POLYESTER), EMS-Griltech 1x dtex 76 f24 x1, Diolen® text. SET trilobal (100% PES), TWD Fibres 1x Lycra 22 dtex, PA 78 dtex, 4495X (93,8% PA, 6,2% EA), Zimmerm. 1x Nm 1,7, Corda (100% PES), Igea 1x Nm 4,8, Topgum (100% PA), Be.Mi.Va. 1x Nm 60/2, Angel (100% SE), Sesia 1x Nm 60/2, K-Wool High Twisted (100% WV), Zegna Baruffa 1x Nm 9, Diver (100% PA), Be.Mi.Va. |

| Time | 1 Leibteil(e) 26 min. 21 sec. @ 1.00 m/sec. |

Fully Fashion Padded Jacket

Fully Fashion Padded Jacket

|

Pattern No. |

2010001 / https://patternshop.stoll.com |

|

Collection |

FASTER: From(CONCEPT)-To(STORE) |

|

Type |

CMS ADF 32 BW multi gauge |

|

Gauge |

E7.2 |

|

Notes |

Stoll-ikat plating®, Stoll-weave-in®, Stoll-artwork® From 1110097 - To 2010001: Padded Fully Fashion jacket with transparent areas. A two-layer multicolour effect is created with multiple weft insertions and plated fine cotton yarns. Neck trimming knitted on CMS ADF 32 B, E18m.16 |

| Yarn |

1x Nm 200/2, York Bright (100% CO), Emilcotoni 2x dtex 76 f23 x2, Timbrelle PA 6.6 HE (100% PA), TWD Fibres 2x Nm 200/2, York Bright (100% CO), Emilcotoni 4x, 5x, 7x Nm 30/2, Cashwool (100% WV), Zegna Baruffa |

| Time |

1 V-Teil(e) rechts 11 min. 48 sec. @ 1.00 m/sec. 1 V-Teil(e) links 12 min. 12 sec. @ 1.00 m/sec. 1 R-Teil(e) 15 min. 3 sec. @ 1.00 m/sec. 1 Zutaten_1 3 min. 21 sec. @ 1.00 m/sec. 1 Ärmel 13 min. 34 sec. @ 1.00 m/sec. |

Downloads

Contacts

Contact

Sandra Peixoto

Portfolio Manager Business Unit STOLL5 – ADF 830

High-tech and multifunctional all-in-one machine to produce the fine knit & wear articles with intarsia, inverse/ikat plating.

Expert Interview

Our expert Michael Sedlag in an interview at ITMA ASIA about the features and application fields of the ADF 830.

-

Videos

Videos

-

Knit & Wear Gallery

Knit & Wear Gallery

-

Fully Fashion Gallery

Fully Fashion Gallery

-

Downloads

Downloads

-

Contacts

Contacts

VIDEOS

ADF knit & wear – STOLL's all-in-one machines (EN)

ADF knit & wear – STOLL's all-in-one machines (CN)

Knit & Wear Gallery

Please browse through the various possibilities of knit & wear garments, that can be produced on the ADF 830.

STOLL ikat plating® / artwork

STOLL ikat plating® / artwork

Knit & Wear Pullover

Crew-neck jersey pullover with french sleeve

机型/ machine: ADF 830-24 W knit and wear E 7.2

产品号 / article: 1910038

原料/ material: 100% Wool

特征 / feature: Stoll-ikat plating® artwork

Running time: 46 min 17 sec

Patternsoftware: M1 plus®

STOLL weave-in®

STOLL weave-in®

Knit & Wear Pullover

Crew-neck jersey pullover with french sleeve

机型/ machine: ADF 830-24 W knit and wear E 7.2

产品号 / article: 1910043

原料/ material: 100% Wool

特征 / feature: Stoll-weave-in®

Running time: 43 min 38 sec

Patternsoftware: M1 plus®

Inverse plating, selective plating, intarsia plating

Inverse plating, selective plating, intarsia plating

Knit & Wear Pullover

Crew-neck jersey pullover with french sleeve

机型/ machine: ADF 830-24 W knit and wear E 7.2

产品号 / article: 1910047

原料/ material: 100% Wool

特征 / feature: Inverse Plating, Selective Plating, Intarsia Plating

Running time: 55 min 51 sec

Patternsoftware: M1 plus®

Inverse argyle with selective plating

Inverse argyle with selective plating

Knit & Wear Pullover

Crew-neck jersey pullover with french sleeve

机型/ machine: ADF 830-24 W knit and wear E 7.2

产品号 / articl: 1910048

原料/ material: 100% Wool

特征 / feature: Inverse Argyle with Selective Plating

Running time: 52 min 17 sec

Patternsoftware: M1 plus®

Shoulder transition in 6-needle neckband

Shoulder transition in 6-needle neckband

Knit & Wear Pullover

V-neck jersey pullover with saddle sleeve

机型/ machine: ADF 830-24 ki W knit and wear E 10.2

产品号 / article: 2110019

原料/ material: 100% Cotton

特征 / feature: Shoulder transition in 6-needle neckband

Running time: 43 min 02 sec

Patternsoftware: M1 plus®

STOLL ikat plating® / STOLL weave-in®

STOLL ikat plating® / STOLL weave-in®

Knit & Wear Pullover

Crew-neck pullover with french sleeve

机型/ machine: ADF 830-24 ki W knit and wear E 10.2

产品号 / article: 2110029

原料/ material: 100% Wool

特征 / feature: Stoll-ikat plating®, Stoll-weave-in®

Running time: 66 min 36 sec

Patternsoftware: M1 plus®

Fully Fashion Gallery

Fully Fashion Sweater N°01 with finest gauge E10.2

Fully Fashion Sweater N°01 with finest gauge E10.2

Swatch for front part of a sweater with set-in sleeve; 3D sweater simulation made in VStitcher by Browzwear

机型 / machine: ADF 830-24 W multigauge

产品号 / article: 2010075

原料 / material : 100% Wool

特征 / feature: Double Jersey, Intarsia

Running time: 11 min

Patternsoftware: k.innovation CREATE Plus®

Fully Fashion Sweater N°02 with finest gauge E10.2

Fully Fashion Sweater N°02 with finest gauge E10.2

Swatch with stripes; 3D sweater simulation made in VStitcher by Browzwear

机型 / machine: ADF 830-24 W multigauge

产品号 / article: 2110016

原料/ material: 82% Cotton, 13% Polyamide

特征 / feature: Variation of pointelle structures and waves

Running time: 16 min 23 sec

Patternsoftware: k.innovation CREATE Plus®

Fully Fashion Sweater N°03 with finest gauge E10.2

Fully Fashion Sweater N°03 with finest gauge E10.2

Front part with colour stripes; 3D sweater simulation made in CLO

机型/ machine: ADF 830-24 ki W multigauge

产品号 / article: 2010076

原料/ material: 100% Wool

特征 / feature: Float jacquard artwork

Running time: 9 min

Patternsoftware: k.innovation CREATE Plus®

Fully Fashion Sweater N°04 with finest gauge E10.2

Fully Fashion Sweater N°04 with finest gauge E10.2

Front part with 3-colour twill jacquard; 3D sweater simulation made in CLO

机型/ machine: ADF 830-24 W multigauge

产品号 / article: 2110008

原料/ material: 100% Wool

特征 / feature: Twill Jacquard artwork

Running time: 11 min 41 sec

Patternsoftware: k.innovation CREATE Plus®

Downloads

Contacts

Contact

Sandra Peixoto

Portfolio Manager Business Unit STOLL2 – KM.ON

Digital Driven Innovation

Expert Interview

Our expert Zhou Fan in an interview at ITMA ASIA about the digital solutions of KM.ON and new product releases.

-

Videos

Videos

- Operational Efficiency: By implementing these systems, textile manufacturers can expect a noticeable boost in their operational efficiency.

- Productivity Gains: The solutions are designed to optimize production workflows, directly contributing to increased productivity levels.

- Informed Decision-Making: Access to in-depth analytics equips manufacturers with the knowledge to make strategic, data-driven decisions.

- Speed to Market: In the fast-paced world of fashion, KM.ON’s design and development tools are invaluable for reducing time to market, from design conception to market release.

-

More Information

More Information

-

Contacts

Contacts

VIDEOS

Pushing the boundaries through digitalization (EN / CN)

k.innovation, k.management & k.production (EN)

KM.ON Digital Solutions

Digital transformation in the textile industry: a glance at KM.ON's digital solutions

In an era in which digitalization is playing an increasingly important role in various branches of industry, the textile sector is also undergoing a transformation. Among the contributors to this change is KM.ON, a company that provides digital solutions aimed at enhancing traditional textile processes. Their tools and software offer a modern approach to improving both efficiency and creativity in the world of textiles.

Enhancing Textile Production

KM.ON specializes in optimizing textile production processes. Their suite includes sophisticated machine monitoring and control systems that bring unparalleled transparency to manufacturing operations. Coupled with robust data analytics platforms, these systems empower manufacturers with actionable insights, leading to improved decision-making and heightened operational efficiency.

Streamlining Design and Development

KM.ON goes beyond production enhancements, venturing into the realm of design and development. Their software applications are tailored to the complexities of knitwear design, digitalizing and streamlining the process from conceptualization to final product. This digital approach significantly accelerates the design-to-market workflow, bridging the gap between creative vision and market trends.

The Impact of KM.ON's Solutions

The advantages of KM.ON's solutions have a wide-ranging impact:

>> Get more information at the website of KM.ON

Contacts

Contact

Marcel Wenzel

Product Manager KM.ONContact

Stefan Winter

Product Manager KM.ONContact

10 – Smart Casual Warp Knits

Innovative, comfortable and eco-friendly warp knitting solutions

Expert Interview

Our expert Song Xiaoqing in an interview at ITMA ASIA about the various applications of smart casual warp knits.

- a very soft touch

- good drape

- crease-resistant properties

- comfort stretch in the cross direction.

- Key features of this fabric are:

- Simple and fast pattern change

- Save garment manufacturing costs

- seamless comfort

- 4-way stretch

- Free-cut suitability

- Light body shaping

-

Fabric Wall

Fabric Wall

-

Fashion Gallery

Fashion Gallery

-

Book Your Webinar

Book Your Webinar

-

Contacts

Contacts

Fabric Wall

3D CRINKLE - Origami

3D CRINKLE - Origami

Machine: HKS 4-M EL + Multispeed

Gauge: E 28

Article Number: 2020/136

Weight: 150 g/m²

Material: 97% Polyamid / 3% Elastan

Much like Origami, this fabric is a result of 3-dimensional folds. By combining a PA/PU core spun yarn in GB1 and GB2 with the multispeed function, a pleated effect is created in the fabric, turning a plain surface into a dimensional structure. The zig-zag structure is created by a partial threading of the core spun yarn and the lapping. In addition to this, the yarn selection and lappings create a fabric that has stretch in all directions.

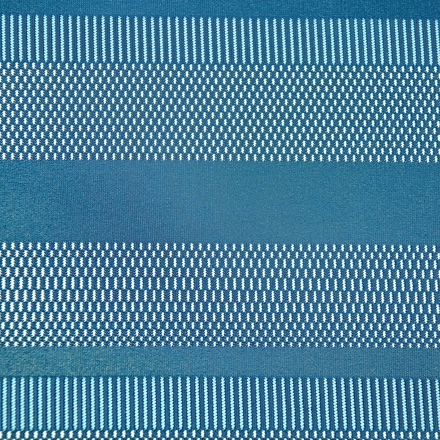

RIPPLE & PLEAT STRUCTURE

RIPPLE & PLEAT STRUCTURE

Machine: HKS 4-M EL + Multispeed

Gauge: E 28

Article Number: 2020/141

Weight: 140 g/m²

Material: 97% Polyamid / 3% Elastan

This tricot fabric with seersucker effect is an extremely comfortable fabric to wear due to its stretch properties and easy care. The puckering effect was achieved by a partial threading of GB 1 and GB 2 with a textured PU/PA core yarn. The core yarn appears here as classy lines, which is only one design option of many. The multispeed function is necessary to produce this structure.

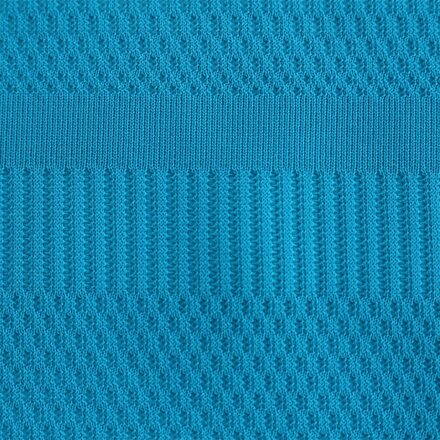

ECO-FRIENDLY 4-WAY STRETCH

ECO-FRIENDLY 4-WAY STRETCH

Recyclable elastic fabric

Machine: HKS 3-M-ON

Gauge: E 32

Article Number: 2020/002

Weight: 200 g/m²

Material: 100% Polyester (DTY & T800)

This fabric is made of 100% pure polyester. Therefore, it can be recycled and returned into the production process. Although this fabric does not contain any elastane, the use of polyester T800 gives the fabric a mechanical elasticity that provides increased comfort for outerwear clothes.

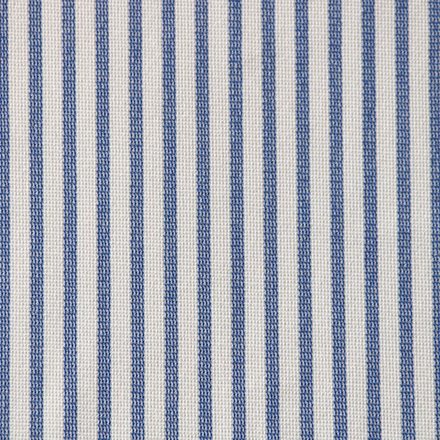

NATURAL STRETCH COMFORT

NATURAL STRETCH COMFORT

Machine: HKS 3-M

Gauge: E 32

Article Number: 2019/052

Weight: 123g/m2

Material: 100% Polyester

This tricot fabric is characterized by

The blue stripes occur due to the use of catonic yarn in GB 1.

SUSTAINABLE RANDOM PATTERN

SUSTAINABLE RANDOM PATTERN

Seamlesss panels for tricots

Machine: HKS 3-M ON

Gauge: E 28

Article Number: 2019/023

Weight: 145 g/m2

Material: 100% Polyester recycled

For this fabric textured polyester 100% recycled was used. This rigid fabric panel for sport applications shows different patterns in horizontal direction which are seamlessly connected. The repeat length of this pattern is 302 courses. Thanks to the ON-drive pattern changes are fast and easy to handle.

JERSEY EVOLUTION

JERSEY EVOLUTION

Machine: HKS 2-S

Gauge: E 40

Article Number: 2019/037

This highly bi-elastic tricot fabric with its delicate shine has been developed for use in intimate wear. With a crosswise elongation of 103% and a lengthwise elongation of 174% paired with an extremely soft touch, this material provides a natural feel and maximum freedom of movement. Due to the two-needle-overlap technique the fabric can attain almost full recovery after relaxation.

FREE CUT RASCHELTRONIC®

FREE CUT RASCHELTRONIC®

Machine: RSJ 4/1

Gauge: E 28

Article Number: 2021/022

Material: Polyamid and Elastan

Characteristics of this lingerie fabric are:

The use of a high-filament polyamide yarn in the jacquard gives this allover pattern a particularly soft touch. Due to the lapping notation the pattern appears to be somewhat three-dimensional.

MULTICOLORED FABRIC

MULTICOLORED FABRIC

Article: DEMO 2160

Materia: 100% PES

Weight: 175 g/m²

Machine: RD 7/2-12 EN

| Double layer |

3D STRUCTURE WITH RANDOM PATTERN

3D STRUCTURE WITH RANDOM PATTERN

Article: DEMO 2159

Material: 94% PES, 6% CORE YARN

Weight: 397 g/m²

Machine: RD 7/2-12 EN

| Fashionable pattern with 3D effect | Good air permeability |

Fashion Gallery

3D CRINKLE FABRIC

3D CRINKLE FABRIC

包芯纱结合特殊的垫纱打造极具创意的面料 / Created by innovative combination of covered yarn and special lapping

机型 / machine HKS 4-M EL E28

产品号 / article 2020/101

原料 / material: 锦/氨包芯纱和锦纶 / Core yarn PA / PUE and PA

| 3D structure | 4-way stretch |

LOUNGEWEAR WITH A GREEN TOUCH

LOUNGEWEAR WITH A GREEN TOUCH

具备环保生产优势的毛圈面料 / Terry fabrics with ecological production advantages

机型 / machine: TM 4-TS EL

产品号 / article: Demo 2158 / demo 2158

原料/ material: 棉/超细涤纶纤维 / Cotton / PES micro

特征 / feature: 经久耐用的防勾丝品质 / snag proof quality for long durability

|

|

|

| Snag-proof | Sustainable production | Double layer |

CROSSOVER LACE BODY

CROSSOVER LACE BODY

在同一幅面料上设计多款装饰性图案 / Different decorative patterns engineered in one fabric panel

机型 / machine: ML 41

产品号 / article: 2019/037

原料 / Material: 59%锦纶 / 41%氨纶 / 59% Polyamide / 41% PUE

特征 / feature: 提升无缝舒适感,降低生产成本 / increased seamless comfort and minimizing of manufacturing costs

| Free-cut | Bi-elastic | Engineered |

FASHIONABLE BRA TOP

FASHIONABLE BRA TOP

精美匀称的贾卡底网 / New fine symmetrical Jacquard ground

机型 / machine: MJ 92/1 B

产品号 / article: 2021/033

| mono-elastic |

CARDIGAN

CARDIGAN

天然叶片设计的时尚针织外套 / Modern knit with natural leaves design

机型 / machine: RJPC 4F NN

产品号 / article: Demo 2091

原料 / material: 100%涤纶 / 100% Polyester

NATURAL STRETCH COMFORT SHIRT

NATURAL STRETCH COMFORT SHIRT

可持续仿机织面料提供舒适的穿着感 / Sustainable woven-like fabric for comfortable wearing

机型 / machine: HKS 3-M or HKS 2-M

产品号 / article: 2019 / 052

原料 / material: 100%再生涤纶 / 100% Polyester recyclable

|

||

| Sustainable production | Water-saving | 4-way stretch |

Learn more on our website: CLEANER.PRODUCTIONS

4-WAY STRETCH WARP KNIT TROUSER

4-WAY STRETCH WARP KNIT TROUSER

节能省水的环保型产品 / environmentally friendly production by using less water and energy

机型/ machine: HKS 3-M E32

产品号 / article: 2020/002

原料/ material: 100%T400涤纶交织 / 100% Polyester blend with T400

|

||

| Sustainable production | Water-saving | 4-way stretch |

Learn more on our website: CLEANER.PRODUCTIONS

BOOK YOUR WEBINAR

We present innovative textile developments with sustainable, eco-friendly, resource-saving and functional aspects. Tricot, raschel and double needle bar fabrics will be presented for fabric manufacturers and brands.

WEBINAR DATES:

05.07.2021 - 09:00-10:00 Uhr (CEST)

>> Registration

13.07.2021 - 15:00-16:00 Uhr (CEST)

>> Registration

SPEAKERS:

Gabriela Schellner, Juergen Wohlrab/Melanie Bergmann, Oksana Wizechowski and Jamie Heather

Contacts

Contact