You weave what you size

Perfect weaving results, thanks to KARL MAYER’s PROSIZE®

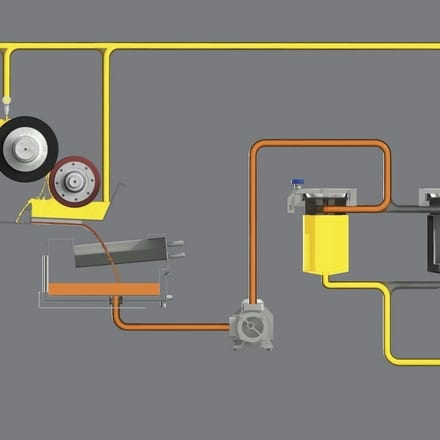

The PROSIZE® sizing machine (Fig. 1) is a bestseller for KARL MAYER ROTAL. This innovative machine was premiered at ITMA 2015 in Milan, and sales have been running into double digits ever since.

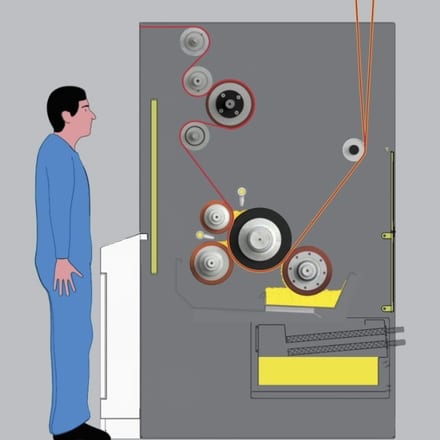

It has been bought by companies all over the world, especially in India, Asia and Western Europe. The range of applications of the machine is as varied as the types of manufacturers that have bought it. The machine’s most important end-use is in garment and home textile production, followed by manufacture of denim and woven shirtings – which occupies second place on the list of most frequent end-uses – and by terry fabrics, bed linen and woollen goods at place 3. The PROSIZE® also offers specific advantages for all the various textile sectors. To illustrate these more clearly, it would be worth taking a closer look at the heart of the PROSIZE®, i.e. VSB and HSB (Fig. 2) size boxes.

Better yarn coverage, improved denim quality

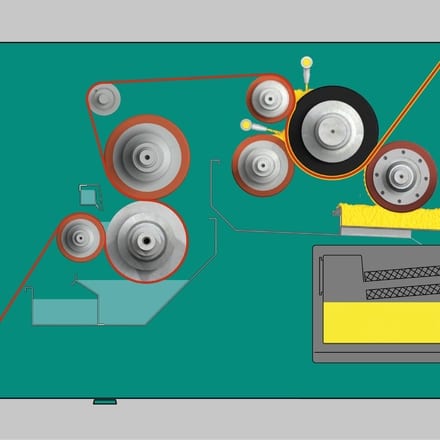

The size boxes operate with an application system for which a patent has been applied and granted. A new feature is that an immersion bath is no longer used. Instead of the usual immersion bath, the size is applied in two, highly turbulent, homogeneous application zones, with spray bar technology and a subsequent application/squeeze roller system (Figs. 3). The so-called sponge effect comes into play here: in the first zone, the dry yarn is dipped into the wedge of liquor between the two rollers, squeezed, and then impregnated again in the second zone. The moist yarn can then absorb the sizing agent more effectively. The bundled yarn feed means that yarn coverage densities of 100% are possible, 20% higher than with conventional immersion processes (Fig. 4). The quality is high, despite the yarns lying very close to each other. Unsized areas are reliably avoided. The higher size uptake and associated yarn coverage density means that the process can be changed over from double to single size box processing in the denim, home textiles and clothing sectors, for example; this is beneficial to the sizing result. The one-bath system simplifies process control and the adjustment of the wetting quality. When producing bed linen, for example, high-quality sized warps can be produced in a working width of 2,800 mm, and there is no risk of the yarns sticking together. The advantages of the one-bath process are being made use of in India especially. Here, a total of 18 customers have invested in a new PROSIZE® machine in the last 24 months, and many of them have even ordered two or more machines. The machines are destined mainly for use in the production of raw woven fabrics.

Lower yarn coverage, increased speed in the terry business

The application system, with its stable yarn feed via the clamping device at the roller pairs, is particularly advantageous at low yarn coverage densities. The lower limit is 20%, which is 10% lower than with conventional technologies (Fig. 4). This is a particular advantage when producing terry goods. These fluffy bathroom textiles are produced with warps having just a few yarns per cm. Because of their twist and moisture content, the yarns have a tendency to twist against each other during sizing and form cords and stick together, especially at high speeds. As the yarns are transported in a guided manner, this negative effect remains. With the PROSIZE®, warps for terry goods can be processed at a maximum speed of 180 m/min, and produced without any superimposed yarns. This represents a speed increase of 20% compared to the ISOSIZE, which can also be used.

Broader yarn coverage, increased productivity when producing home textiles

In addition to the density, the width of the yarn coverage can also be increased. This is also due to the guided passage of the yarns through the size box, but especially to a special design feature. Thanks to this clever design, the rollers support each other. There is no bending, even at large working widths. This makes the size coating extremely uniform, the yarns do not stick together, and a new PROSIZE® with a working width of 3,200 mm has emerged. This wide machine is particularly suitable for producers of home textiles, who process large fabric webs. The example of a Portuguese high-end manufacturer shows the advantages quite clearly: this company uses a sizing machine with a working width of 1,800 mm and a single size box to produce warp beams comprising 9,000 yarns. Two of these beams are processed on one loom. With the new PROSIZE®, the required number of yarns can be treated at a higher coverage density on just one warp beam, which increases efficiency and productivity considerably. Single beam processing also improves the quality, i.e. the yarns that are to be woven come from the same sizing process and thus have an identical size coating.

Fewer rejects in the event of stoppages, fewer losses in shirt production

The spray technology avoids yarn rejects in the event of long machine downtimes. This differs from immersion process, i.e. if the machine stops, the yarns remain at this position in the size and the stoppage marks prevent them from being used. This is a real disadvantage, especially when the warps have to be changed frequently and quickly, such as when producing high-quality shirtings. Short runs and frequently changing colours are required in this sector. The spraying process also offers advantages when processing multiple colours, i.e. in conjunction with fine filtration, transfer between the colours of the yarns is avoided.

Small bath volumes, lower costs, reduced environmental impact and less splashing

The clever process design allows smaller bath volumes to the used, and thus reduces the consumption of size additives (by as much as 10%). Effluent loads, and the time and effort needed for desizing are also decreased. Less liquid also means less splashing. The concentrated liquid flow also reduces sizing agent losses and enables the ergonomics to be optimised, i.e. there is no need for a splash protection device, and free access to the size application system is guaranteed, e.g. for cleaning and dealing with yarn breakages. Vertical delivery of the warp sheet (Fig. 5) also means that the VSB makes even more space available for carrying out simple manual adjustments. The operative also has an unrestricted view of the entire process.

Greater uniformity in sizing, better efficiency in weaving

Thanks to the intensive size circulation in the highly turbulent application zones, dead zones are avoided and concentrations, temperatures and viscosities are equalised. The size layer on the circumference of the yarn is also uniform. The clever roller arrangement means that the warp yarns in the wedge absorb size on the upper and lower sides. Furthermore, only size that has been filtered is applied to the yarn. This performance produces an extremely uniform coating over the width and length of the warp, which is beneficial for the subsequent stages in the value-added chain. Much less fibre fly is generated in weaving, which increases efficiency considerably (Fig. 6).

Back to overview